Colloids

and Surface Phenomena

Aspects of Makeup and Lipstick

Group 6

CHAIN, KOK KEONG

LE, DIEUHANH THI

MCLAUGHLIN, KELLY E

VAN NATTER, RAINEE M

Date: 9th April 2002

Introduction

In recent years, the rise of

the worldwide living standard has created a path for the increasing use of

cosmetic products. The featured article by the R & D in the Cosmetic Age

has reported that the global personal care market that includes skin care,

makeup, hair care and fragrance products is estimated to be $125 million. The

consumer demands that cosmetic products be high quality, safe for daily

application without creating any long or short term side effects to skin,

reasonably priced to be affordable by the working class, containing ingredients

that have multiple abilities and two in one formulations, and long-wearing by

resisting moisture. In order to meet

these challenges, application of polymers and surfactants play an important

role in modern cosmetic products. The

functions involve the encapsulation of the active ingredients for later

release, lowering the surface tension between the materials and skin, aiding in

firm distribution of the cosmetics ingredients, promoting adhesiveness, and

reducing allergic reaction with skin. Cosmetics vary

greatly in formulation and this creates differences in texture, color, and

physical and chemistry properties. In general, cosmetics ingredients are

classified into vehicle group and active ingredients. Vehicles are spreading

agents but do not alter the appearance of the skin. Active ingredients

including emollients, humectants, binders and surfactants cause changes in the

physical appearance such as smooth finish (R&D, J.Mufti and R.Macchio).

A polymer is a chemically

manufactured gel like, long chain carbon with cross-linked conformation. The

active ingredients such as emollients and vitamins are loaded during the

polymerization processes. The spherical bead has high internal surface areas,

from 200 to 500 m2/g, created an ideal sorption and desorption mechanism

to serve as carriers for the oil soluble active ingredients (R&D, J.Mufti and R.Macchio). The

positively charged surface of the polymeric membrane make it favorably adhered

to the mildly negatively charged skin surface. Consequently, it helps in distributing

the ingredients evenly on skin.

Surfactant or surface-active agents possess a chemical structure that consists of head and tail components. The hydrophilic head group has strong attraction to solvent or bulk material, while the hydrophobic tail with long chain hydrocarbon behaves oppositely. Distortion of the water structure by surfactant in aggregation or micellation process helps to lower the energy of the system, thus improving the interfacial adsorption. Micelle formation is important due to the thermodynamic stabilization in solution behaving as dispersed species. Suitable solvent environments will determine the best chemical structure for use in a given cosmetic system. Emollients, wetting agents, and emulsifying agents are typical surfactants that are used to promote lubrication, adhesiveness, slip and covering. Emulsifiers include an anionic, cationic or nonionic surfactant. This ingredient has made the union of water and oil possible. Emollients are used to soften and smoothen the skin. Humectant has the ability to hold and retain the moisture respirated from the skin. Both the liquid and solid binder is used to provide cohesion. Cosmetic colorant is essential to give color to the cosmetic so it is pleasing to consumer and to impart suitable color appearance on the skin (Happi, J.Mufti). In the following report, the discussion will concentrate on efficiency of the application of surfactant and polymer in four types of cosmetics that are widely used. They are lipstick, eye shadow and blush, face powder for both dark and pale skin, and liquid creams.

Lipsticks

Lipstick

in some shape or form has been around for a long time and has always been a

part of the fashion statement. Lipstick

is a true icon of the feminine mystique. Its allure and seduction goes

back thousands of years. Lipstick can transform, re-invent, brighten and

finish. Lipstick is one product that has more choice than anyone could ever

require. Five basic categories of

lipsticks are matte, high gloss, long lasting, satin and frosted.

Matte

is a flat, stained look with no gloss. This is a long-lasting lipstick but can

be drying. Matte lipsticks have more

wax than other types of lipstick but fewer emollients. High gloss has a shimmery appearance and

helps make lips appear fuller. High

gloss lipsticks can be sticky and tend to wear off quickly. Long-lasting lipsticks contain silicone

oil. Silicone oil helps to keep the

color on the lips and allows the lipstick to stay on all day long. Only mineral oil takes it off. Most lipsticks have a satin finish. Satin is a combination of gloss and

matte. Satin lipstick is creamy, which

moisturizes the lips, but is not as greasy as other types of lipstick. Satin lipsticks are preferred by many women

today. Frosted lipstick contain pearlizing agents. Pearlizing agents are generally bismuth compounds which add

luster to the lipstick (ACS).

Lipstick contains a variety of emollients,

emulsifiers, preservatives, colorants and binders. According

to Ultra Chemical Inc., the emollient ingredients for lipsticks are Lipovol CO,

caprylic triglyceride and isostearyl isostearate (UltraChem – lipstick). Lipovol or castor oil can be obtained from

the castor plant (essential) and has a preferred weight percent of 51.6 in the

Ultra Chemical formulation (UltraChem – lipstick). Castor oil creates a protective barrier on the skin (essential)

and forms a film when it dries (ACS).

Caprylic triglyceride, used at 10 weight percent in the Ultra Chemical

formulation (UltraChem – lipstick), is an oily liquid that can be obtained from

plants, vegetable oil, and dairy fats.

It also can be synthesized from coconut oil or palm kernel oil

(csmt). Isostearyl isostearate has a

preferred weight percent of 10 in the Ultra Chemical formulation. It acts as an emollient (UltraChem -

lipstick).

Lipstick contains a variety

of waxes for emulsifiers, including ozokerite wax and paraffin wax (UltraChem –

lipstick). Ozokerite is a ceresin wax and is a naturally occurring mineral wax

(csmt), and is used at 1.0 percent by weight in Ultra Chemical formulation

(UltraChem – lipstick). Paraffin wax is

derived from petroleum (csmt) and is used at 2.0 weight percent in the Ultra

Chemical formulation (UltraChem - lipstick). The function of the waxes is to

give lipstick its shape and make application easier (ACS). Perfluorocarbons are used in lipstick to

increase the interfacial surface area between the pigment and the wax

bases. This larger interfacial boundary

is ideal for entrapping water within the lipstick, causing it to feel

moist. However, the trapped water

creates two issues affecting the stability of the lipstick. The first involves packaging. The lipstick must be packaged in an airtight

container to avoid the evaporation of the water in the lipstick. The second involves electromagnetic force

stability of pigments, which is affected by the pH at the surface of the lips

(stepex). Other ingredients in lipstick

include emulsifiers. An emulsifier is a

chemical compound that allows oil and water to form a stable mixture, which is

called an emulsion. Due to both a hydrophobic and hydrophilic end of the

molecule, an emulsifier is able to attract both water and oil (essential).

The compound used as a preservative

agent in lipstick is propyl paraben.

Propyl paraben has a proper name of propyl-4-hydroxybenzoate (essential)

used at 0.1weight percent in the Ultra Chemical formulation (UltraChem -

lipstick). It is prepared from

p-bromophenol by

adding hydrogen gas under high pressure to a liquid oil in order to obtain

semisolid fats. Propyl paraben is the

most common preservative because of it is a nontoxic compound that does not

irritate the skin. Also, it is stable over a broad range of pH values and is

water-soluble (essential). It has both fungicidal and antibacterial properties, which help to

prevent the growth of yeast and mold in the lipstick (csmt).

Lipstick

gets its color from a variety of added pigments. Among them are D&C Red #7 CA Lake, Ultrapure HMP-S, and Red

Oxide (UltraChem – lipstick).

Ultrapure HMP-S is a petrolatum product created to add color to

lipstick. It is a petrolatum and wax

blend that combines the ideal properties of each. The wax portion gives the mixture a high melting point and

stiffness, while the petrolatum gives the mixture moisturizing properties

(UltraChem - petrolatum). The color agents are based on red oxide or titanium

dioxide with iron oxides, occasionally in combination with ultramarine

blue. Titanium dioxide acts as a facial

concealing or covering agent (UltraChem - lipstick). Coloring agents used in lipsticks must be safe because it is used

so close to the mouth.

Candelilla

wax is used as a binder compound. The genetic name of Candelilla Wax is

Euphorbia antisyphilitica (essential), and it is used 3.0 weight percent in the

Ultra Chemical formulation (UltraChem – lipstick). Candelilla wax is obtained from the candelilla plant (csmt). It

is produced by soaking the plants in a solution of sulfuric acid and boiling

water and then skimming the wax from the surface (ACS).

The following table shows the compositions of the components in matte lipstick (UltraChem – lipstick).

COMPOSITION

COMPONENTS RANGE % BY WEIGHT PREFERED BY WEIGHT

(1) Candelilla Wax (Wax) 3.00 - 9.00 3.0(2) Ozokerite (Wax) 1.00 - 4.00 1.0(3) Paraffin Wax (Wax) 2.00 - 5.00 2.0(4) Ultrapure HMP-S 8.00 - 10.00 10.0 (5) Isostearyl Isostearate 2.00 - 10.00 10.0 (Emollient)(6) Capric/Caprylic Triglyceride 2.00 - 10.00 10.0 (Emollient)(7) Castor Oil (Emollient) QS 51.6(8) Propyl Paraben (Preservatives) .10 .1(9) Tocopheryl Acetate (Antioxidant) .10 - 1.00 .1(10) Colorants : D&C Red #7 CA Lake .00 - 4.00 .3 Red Oxide .00 - 3.00 1.5(11) Rhapsody Talc 4M 2.00 - 10.00 10.0(Filler/Matrix) Total 100.0

To make lipstick, the ingredients besides the waxes and oils are

pulverized. Then, the waxes are added,

along with the oils (ACS). The mixture

of ingredients is heated to 75ºC to 85ºC and mixed until the batch is smooth

and uniform (UltraChem - lipstick). The

hot mixture is formed into its shape by cooling it in metal molds. Imperfections are removed by putting the

cooled lipstick in a flame for approximately half a second, which also gives

the lipstick its finish (ACS).

Recently, ingredients have been added to lipstick formulations for

various reasons. Sunscreen is added to

prevent lips from becoming sunburned, while aloe vera and vitamins are added to

keep lips soft and moist (ACS).

Eyeshadow and Rouge

The sole purpose of eyeshadow and rouge is to provide color. In order

to satisfactorily achieve this goal, the cosmetic must contain pigments, adhere

to skin, have adequate slip to spread onto skin, and have limited water and oil

solubility for decent wear in varying conditions, in other words not run with

perspiration. In addition, the cosmetic should be easily removable with

cleansers. The cosmetic must also be safe for skin and eyes.

Both eyeshadow and rouge may be found in several forms. Rouge may be

found as a liquid suspension or emulsion, a cream, a lipstick-like solid, or as

a dry, compact powder. The liquid form contains pigments suspended in water,

alcohol, glycerol, or other fluid emulsion. Eyeshadow can be found in dry,

compact form, as well as a thick, creamy, almost solid form.

Today, of the above, the dry

compact is the most common type to be found. Application is done with the use

of a powder puff, brush, or sponge or fabric applicator. The solid form is

similar in composition to lipstick, and, in fact, some women use lipstick as a

substitute for rouge, though solid rouge will have a much more diluted color

than lipstick. It is applied and then blended. The creams and emulsions are

applied and blended with the fingers, which has probably led to the higher

popularity of the dry, compact form. (Sagarin 229-255).

Mascara is available today

in liquid form. In mascara, a low molecular weight polyethylene is used to form

a gel with the solvent to suspend the color. The object is to leave a pigmented

film on the lashes after evaporation of the solvent (Poucher III 305).

Pigments are strongly colored substances. Since the sole purpose of

eyeshadow and rouge is to provide color, pigments are important ingredients,

which will be present no matter the type of eyeshadow or rouge. They provide

the color for the cosmetic. In order to be ideal for use in cosmetics, pigments

should not change color with pH changes, water, or oil, and should have limited

solubility in water and the oils found in perspiration. Otherwise, color may

bleed or streak, or change during wear, which is generally not desired in

eyeshadow, and especially not rouge. Pigments should not fade significantly

when exposed to light, though organic pigments will fade to some extent. Since

powder-milling may involve high temperatures, the pigments must be heat stable.

The pigments should also be relatively easy to add into the product. This will

affect the choice between whether to use a pigment in the form of a dry powder

or a wet pulp or solution. It is of course necessary that the pigment be

non-toxic. This is untrue of many of the most brilliantly colored pigments,

such as lead and arsenic salts, which were often used in the past to much

detriment. It is also important that all pigments used be of same particle

size, otherwise rubbing of finished product will bring out the colors of

largest size (Sagarin 229-235), (Poucher III 283).

Pigment particle size will affect the result of the final applied cosmetic. Pigment particles should be sufficiently reduced in size and thoroughly blended with the rest of the formula to prevent streaking. Large particle sizes in the pigments scatter light better and increase opacity. It is important to note here that the cosmetic color when applied will differ from that in the compact. Color in the compact is the result of light being reflected from the powder surface itself. On skin, the pigment will be in a thin film, allowing light to be transmitted through it rather than reflected from its surface. This defines the undertone of the cosmetic pigment. This is often tested by wetting the finished powder with a little mineral oil and spreading on a flat white surface. The color will also be affected by the color of the skin (Sagarin 230-232,234).

The following are some of the common pigments found in eyeshadow and

rouge. Most of the white pigments also serve as opacifiers, giving the rouge or

eyeshadow more opaqueness or coverage. Organic Pigments, which can be found at

the bottom of the following list, tend to be brighter and more vibrant (Sagarin

233).

|

Pigment |

Structure |

Color(s) |

Additional Information |

References |

|

Talc |

MgO·4SiO2·H2O |

White |

Main Ingredient in Powder

cosmetics. |

Marmion 106 |

|

Zinc Oxide |

ZnO |

White/yellowish white |

Opacifier, slight drying

affect on skin. |

Marmion 108-109, Sagarin 228 |

|

Titanium dioxide |

TiO2 |

White |

Much better opacifier than

zinc oxide, but has a tendency to produce blue undertones and doesn’t blend

well with other ingredients.. |

Marmion 107, Sagarin 228 |

|

Mica |

K2Al4(Al2Si6O20)(OH4)

or H2KAl3(SiO4)3 |

White, pearlescence |

White powder obtained from the naturally occurring

mineral, muscovite mica. Provides pearly luster. Also an opacifier. |

European Commission Andersen Marmion 111 |

|

Carbon black |

C(s) |

Black |

May be used from any

source, animal or vegetable. |

Sagarin 233 |

|

Iron Oxides |

Fe3O4 |

Black |

Iron oxides must be

synthetically prepared |

PCI, Andersen |

|

Iron Oxides, ochres, umbers |

Fe2O3 |

Red, brown |

ochres: iron ore known as

hematite, containing 60 to 80% Fe2O3. Umber is a brown

ochre. Synthetic brown iron oxide obtained by controlled oxidation of

precipitated ferric hydroxide, resulting in a mixture of red Fe2O3

and black Fe3O4. |

PCI, Sagarin 233 |

|

Iron Oxides, Yellow ochres |

Fe2O3·H2O (FeOOH) |

Yellow-orange |

Yellow ochre: Clay colored

with up to 25% hydrated ferric oxide, Fe2O3·H2O. |

Sagarin 233 PCI |

|

Siennas |

|

Yellow, Brown |

Sienna (yellow): Mixture of

hydrated oxide plus some manganic oxide. Burned sienna is a brown pigment. |

Sagarin 233 |

|

Ultramarines |

~Na7Al6Si6O24S3 |

Blues, violets, greens,

pinks, reds |

The ultramarines were

originally made from the powdered naturally occurring semiprecious gem,

lazurite (Lapis lazuli). They are now synthesized from kaolin, silica,

sulfur, soda ash, sodium sulfate, and rosin or charcoal pitch. Used in

eyeshadow and mascara. |

Sagarin 233, Marmion 108, Andersen |

|

Chromium oxides, hydroxide |

Cr2O3,

Cr2O3·3H2O |

Yellowish (sage) green,

bluish green |

Anhydrous Cr2O3

(sage green) has good opacity and stability. (Cr2O3); Hydrated or Guignet’s

green (bluish), Cr2O3·3H2O, is somewhat

transparent. |

Sagarin 233 Marmion 100-101 |

|

Aluminum powder |

Al (s) |

Silver |

|

Sagarin 233 |

|

Ferric Ferro-Cyanide,

ferric ammonium ferrocyanide |

Fe4[Fe(CN)6]3XH2O,

|

Prussian blue |

|

Marmion 110, Jones, “True Blue” |

|

Manganese Violet |

~Mn3+NH4P2O7 |

violet |

Obtained by reacting

phosphoric acid, ammonium dihydrogen orthophosphate, and manganese dioxide at

temperatures above 450°F. |

Marmion 111 |

|

Bismuth Oxychloride |

BiOCl |

Pearly lustre |

Synthetically prepared

pearlescent pigment. |

Andersen, Marmion 109 |

|

Carmine (Carminic acid) |

C22H20O13

|

Orange-red, Rich

purplish-red, pink |

Carmine is ~50% carminic

acid, which is extracted from cochineal beetle., little solubitity in most

solvents, can be solubilized by strong acids and bases. |

Andersen, Marmion 99-100 |

|

Guanine |

C5H5N5O

|

Iridescence |

Crystalline material from

fish scales. Used to provide iridescence. Typically supplied as a paste or

suspension in water, castor oil, or nitrocellulose. Silvery or pearly white,

though other pigments may also be in the fish scales, which may change the

product color. |

Andersen, Marmion 101 |

|

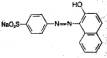

Lithol Rubin B |

C18H12N2O6S(Na2/Ca)

|

Medium dark red with blue

undertone |

D&C Red No. 6 (at

left), 7 |

Marmion 77, Sagarin 235 |

|

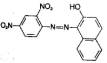

Lake red C |

C17H12N2O4S(NaCl/Ba1/2Cl)

|

Scarlet |

D&C Red No. 8 (at

left), 9 |

Sagarin 235, Marmion 78-79 |

|

Tetrabromofluorescein |

C20H8O5Br4

|

Med. Red w/ blue undertone |

D&C Red No. 21 |

Sagarin 235, Marmion 80 |

|

Rhodamine B |

C28H31N2O3Cl

|

Bright cerise (red) w/

yellow cast |

D&C Red No. 19 |

Sagarin 235, Marmion 79-80 |

|

Flaming Red |

|

Bright orange |

D&C Red No. 36 |

Sagarin 235, Marmion 84-85 |

|

Persian Orange |

|

Transparent orange |

D&C Orange No. 4 |

Sagarin 235, Marmion 74 |

|

Permatone orange |

|

Bright opaque orange |

D&C Orange No. 17 |

Sagarin 235, Marmion 76 |

|

Acid Fuchsine |

|

Red |

D&C Red No. 33 |

Sagarin 235, Marmion 83-84 |

|

Allura™ Red AC |

|

Red |

FD&C Red No. 40 |

Sagarin 235, Marmion 67 |

|

Tartrazine |

|

Yellow |

FD&C Yellow No. 5 |

Marmion 67-68 |

|

Brilliant Blue FCF |

|

Blue |

FD&C Blue No. 1 |

Marmion 53,64 |

Talc is the main ingredient

in dry compact makeup, composing approximately 60 to 90 weight percent of the

product. It is a magnesium silicate with the approximate formula 3MgO·4SiO2·H2O.

It is a naturally found material, not synthesized. “The good grades possess a

lamellar structure which shows cleavage in the same manner as mica. This

property accounts for the shine and slip of the material” (Sagarin 223-224). It

is also a very soft material. Mined talc varies in grade, so properties range

from shiny to dull, white to dark grey in color, and in softness. Talc adheres

to skin evenly and absorbs oil and moisture. These properties, as well as the

softness, and “slip” of cosmetics grade talc make it ideal for use as the main

ingredient in compact rouge and eyeshadow.

Talc particles are sifted

and milled, so that almost all of the particles are no larger than 74 microns.

Even finer “micronized” talc is available. The size of the talc particles is

important. If the talc particle size is too big, it will not adhere well to the

skin. If the size is too small, the talc structure and corresponding properties

are lost. (Marmion 105-106), (Sagarin 223-225), (Poucher I 350).

In liquid or gel blushes, the main ingredient

is usually water. In cream eyeshadows or blushes, it tends to be

binder-emollients such as caprylic/capric tryglyceride or octyl palmitate. In

solid rouges, the main ingredient is often castor oil, as in lipsticks.

Binders are substances which

are added to solid cosmetic mixtures to provide cohesion. Emulsifying agents

promote the mixing of otherwise immiscible liquids. Surfactants lower surface

tension, thereby promoting more even mixing. Most blush and eyeshadow is sold

in dry compact form, in solid lipstick-like form, or in an almost solid cream

form. Thus, binders and emulsifiers are very important in holding the cosmetic

mixture together. They hold pressed powder cosmetics together, improve emulsion

stability and shelf-life, and allow the cosmetic to form a continuous film on

skin when applied. The choice of binders is important in the manufacture of dry

compact cosmetics, since inadequate binders will cause the product to crumble

in the compact as well as on application. Poor or no emulsifiers will lead to

an unmixed mess of ingredients in emulsion eyeshadows. Emollients are also

included in this section since many of the emollients used in cosmetics also

serve as binders for pressed powder cosmetics. Emollients soften and smooth the

skin. They are important in keeping cosmetics from drying out skin. The most

commonly used binders are described below (“European Commission”), (Sagarin

257).

Zinc and Magnesium Stearate

act as binders in dry form. In addition, they coat the powder particles, making

the powder more waterproof. They also make the powder more apt to adhere to the

skin. Because of the ease of mixing in dry ingredients and the properties

described above, zinc or magnesium stearate can be found in almost every powder

makeup formulation (Sagarin 227, 256, 257-258), (European Commission).

Squalane, C30H62,

is a binder and emollient. It is a liquid miscible with vegetable and mineral

oils (European Commission),(Poucher I 344).

Caprylic/capric triglyceride is the mixed triester of glycerin and

caprylic and capric acids, having 8 and 10 carbons in the chain, respectively.

They are derived from coconut oil, and serve as an emollient and solvent in

cream-type eyeshadows and blushes (“Product Dictionary”), (European

Commission), (Sagarin 390).

Octyl Palmitate is also an

ester emollient and binder. It is a liquid, and serves as a solvent in the

formulation of cream-type eyeshadows, as well as a binder in powder cosmetics.

Mineral oil, a liquid blend

of hydrocarbons obtained from petroleum, and petroletum have largely been used

as bases in cream eyeshadow in the past, though they have largely been replaced

by the vegetable oils above, since they are much more skin friendly (“Product

Dictionary”).

Waxes are a complex

combination of hydrocarbons obtained from petroleum fractions. They consist

mostly of straight chain hydrocarbons with a length great than 20 carbons.

Waxes serve as binders, emulsion stabilizers, emollients, and viscosity

controlling agents. Beeswax, in particular, is used in stabilizing water-in-oil

emulsions in making cosmetic creams (European Commission), (Poucher I 50).

Ozokerite or ceresin (its purified form) is a mineral wax. It is a complex

combination of hydrocarbons consisting predominantly of saturated straight

chain hydrocarbons with 20-50 carbons each. It is used as a binder and emulsion

stabilizer. It is also used to raise the melting point of solid cosmetics, and

is a substitute for beeswax or hard paraffin in this respect. (European

Commission), (Poucher I 96-97).

Isopropyl Myristate is a

synthetic fatty acid ester, and a liquid binder (Sagain 288).

Castor and safflower oils

are both emollients used in cosmetics. Castor oil is the main constituent in

solid rouge and consists primarily of the glycerides of the fatty acid

ricinoleic. Safflower oil consists primarily of the glycerides of the fatty

acid linoleic. (“Product Dictionary”).

Glycerin, also known as

Glycerol or propan-1,2,3-triol, acts as a solvent to dissolve other components

and as a humectant, meaning that it serves to hold and retain moisture in the

cosmetic product. It is prepared by the hydrolysis of fats and oils. It has the

formula CH2OHCHOHCH2OH (European Commission), (“Product

Dictionary”), (Poucher I 181).

Cetyl alcohol, C16H33OH,

is a waxy powder. It is stable in the presence of acids, alkalis, light and

air. It is soluble in alcohol, ether, glycol, and diglycol ethers and miscible

with mineral and vegetable oils and fats. It serves as an emulsifying agent for

both oil-in-water and water-in-oil emulsions. It also serves as an emollient

(Poucher I 97-98).

Lanolin is the fat extracted

from the wool of sheep. It is an emollient readily absorbed by the skin. It

consists of a complex mixture of esters of high molecular weight fatty alcohols

and acids. Liquid lanolins are soluble in mineral oil (Poucher I 214).

Oleyl alcohol, C18H35OH, serves as an emollient, emulsion stabilizer,

super fatting agent, and a “pigment dispersing material”. It is used to improve

the texture of creams and in stick cosmetics. It is soluble in ether and

alcohol and insoluble in water (Poucher I 283).

Diethylene glycol

monostearate (C17H35COOCH2CH2OCH2OH)

is an emulsifying agent for the preparation of oil-in-water emulsions (Poucher

I 142). As a chain hydrocarbon with a polar end, it makes a good surfactant.

Preservatives are added to

cosmetics to inhibit the growth of micro-organisms within. From a safety

standpoint, preservatives are most important in eye make-up, and especially in

mascara, where it is possible to cut the eye with the applicator wand and

infect it. Bacteria will especially be a problem in water-based cosmetics,

where bacteria will grow readily. (Draelos),(Stehlin), (European

Commission). Preservatives frequently

used in cosmetics are listed below.

The

parabens are esters of p-hydroxybenzoic acid (C6H4OHCOOH)

. They are the most commonly used preservatives in cosmetics today. They

include methylparaben (methyl parahydroxybenzoate), which is water-soluble,

ethylparaben (Ethyl 4- hydroxybenzoate), propylparaben (Propyl 4-

hydroxybenzoate), which is less water soluble than methylparaben, and

butylparaben, which is oil-soluble (Poucher I 197-198), (“Product Dictionary”),

(European Commission).

Glyceryl Monolaurate

(monoglyceride) (empirical formula C15H30O4)

is both a preservative and a good emulsifier, distributing between both

lipophilic and hydrophilic phases of formulations, which helps to make it a

cost effective preservative (Utlra Chem).

EDTA (Ethylene Diamine Tetra Acetic Acid) is a synthetic compound used

mainly in lotions as a preservative (“Product Dictionary”). Imidazolidinyl

Urea (N, N''- methylenebis[N'- [3-

(hydroxymethyl)- 2, 5- dioxoimidazolidin- 4- yl]urea]) is another preservative

(“Product Dictionary”), (European Commission).

The

role of absorbents is to take up excess water and oil, such as from

perspiration, and to lower the shine created by the talc in powder cosmetics,

if so desired. Perfume carriers tend to be absorbent materials.

Magnesium carbonate is an

absorbent due to the high porosity of magnesium carbonate. However, excessive

absorption of perspiration may cause gumminess and streaking if there is too

much magnesium carbonate in the formula. Magnesium carbonate may also cause

drying. It removes the shine of talc. It is also a perfume carrier and slight

opacifier. Too much magnesium carbonate will make a compact brittle because of

the absorbency. It is decomposed by acids. (Sagarin 226-227,256). Kaolin (2SiO2Al2O3·2H2O)

is an absorbent and removes the shine of talc. It also has soothing properties.

Unfortunately, it causes many perfumes to deteriorate. Chalk is used as a

perfume carrier. Only a small amount may be used as it tends to make compacts

brittle (Sagarin 225-227,256).

Sample eyeshadow, rouge and mascara formulations are given in the tables below, along with a description of the manufacturing process.

Dry Rouge:

|

(Almay) |

Talc (Filler) 48% Kaolin (Absorbent) 16% Titanium Dioxide (Opacifier) 12% Color Pigments 12% Zinc stearate (Binder) 4% Chalk (Perfume carrier) 4% Magnesium carbonate (Perfume carrier) 4% Perfume q.s. (Sagarin 261) |

|

In older processes which

required less equipment, the pigments, including the titanium dioxide, and dry

powder ingredients, were first pre-mixed in spiral ribbon or pony mixers.

Binder solution or water was added to convert the mixture into a dough-like

paste. The paste was then dried in ovens on shallow trays. The hard, dry cakes

were then reground in hammer or ball mills. These operations were then

repeated. A fairly large amount of binder was used, and operators could tell if

the binder was uniformly distributed.

In the more modern

“American” process, more powerful grinders are used, which precludes the need

for wetting and baking cycles. Hammer mills with air classifiers, cyclone

mills, attrition mills, and edge runner mills are used. A fairly small amount

of binder and emulsifier is sprayed into the powder while it is being mixed.

The emulsifiers act as wetting agents and are needed to make sure that the

binder is evenly distributed. This is especially so if the binder contains

water since the powder is usually water repellant.

The mixed rouge is then distributed into pans and then pressed. A small amount of air should be left between the press and the edge of the pan to allow for the escape of air from the interstices between the powder particles. The press should bring the powder particles into physical contact with each other and then “weld” the binder film around each particle to that of the adjacent particles (Sagarin 258-261).

Liquid-Gel Rouge:

|

(L’Oreal) |

Water (softened or distilled) 67% Glycerin (solvent) 19% Diethylene glycol monostearate (emulsifier) 4.3% Cetyl alcohol ethoxylate 2.9% Titanium dioxide 2-3% Pigment 2.0% Iso-Propyl myristate (binder) 1.9% Cetyl alcohol (emulsifier/emollient) 0.48% Perfume 0.2% Methyl paraben (preservative) 0.15% Bromo acid (colourant) 0.02% (Poucher III 284) |

|

The emulsion base is prepared by heating together the cetyl alcohol

ethoxylate, iso-propyl myristate, cetyl alcohol, and diethylene glycol

monostearate to a temperature of 70-75°C. In a separate vessel the methyl

paraben is dissolved in the glycerine by heat. The water is added to the

glycerin and heated to 75°C. The water-glycerin mixture is then added to the

emulsion base with slow continuous stirring, and allowed to cool with continued

stirring. The perfume is added when the temperature reached about 35°C. Then,

the pigment, including titanium dioxide, is added and the mixture mixed well

(Poucher III 284).

Solid Rouge:

|

(Wet N Wild) |

Castor Oil 77.4% Candelilla wax 9.9% Carnauba wax 2.7% Color 10.0% Perfume q.s. (Sagarin 254) |

More details about these ingredients and the manufacture can be found under “Lipstick.” |

Dry Eyeshadow:

These formulations are very similar to those of compact rouge.

|

(Almay, Inc.) |

Talc (Filler) 64.7%(wt) Ultramarine Blue (Pigment) 20.0% Octyl Palmitate (Liquid Binder) 7.0% Squalane (Liquid Binder) 3.5% Iron Oxides (Pigment) 2.6% Zinc Stearate (Solid Binder) 2.0% Glyceryl Monolaurate

(monoglyceride) EDTA (Preservative) 0.1% (UltraChem - eyeshadow) |

|

The pigments, preservatives, and zinc stearate are combined with an

equal portion of talc. The mixture pulverized and blended with the remaining

talc. The oil-phase binders (octyl palmitate, squalane) are sprayed and mixed

into the powder. The mixture is then compressed into suitable containers

(UltraChem - eyeshadow).

Creamy Solid Eyeshadow:

|

(Black Opal/BioCosmetic Research Labs) |

Petroleum jelly* (binder/base) 25.6% Paraffin wax (binder/emollient) 22.6% Isopropyl palmitate (binder/emollient) 16.4% Lustre Pigments 10.3% Pigments 8.2% Beeswax (binder/emollient) 5.1% Oleyl alcohol (emulsion stab.) 5.1% Lanolin (emollient) 4.1% Cetyl alcohol (emulsifier/emollient) 3.1% Perfume 0.5% Butylparaben (preservative) 0.02% Propylparaben (preservative) 0.01% (Poucher III 294) |

|

The isopropyl palmitate, petroleum jelly, oleyl alcohol, and lanolin are heated together, and the preservatives are added. The pigment is mixed into the melted mixture and milled. The waxes are melted, and then added to the mixture, along with the luster pigment. The mixture is allowed to cool. Perfume is added after cooling. The mixture is then poured into moulds and allowed to set (Poucher III 294).

Today, the petroleum jelly is almost always replaced by caprylic/capric triglyceride.

Mascara:

|

|

Isoparaffin (Solvent) 69.7% Pigments 12.0% Beeswax 5.4% Ozokerite wax 5.4% Polyethylene 4.2% Carnauba wax 2.0% Microcrystalline wax 1.2% (Poucher III 305) |

|

The polyethylene is mixed with about half the solvent using a propeller

type mixer with moderate agitation. The mixture is heated to about 100°C with

stirring. The remainder of the solvent is added and the mixture is cooled

rapidly. Rapid cooling is essential for the preparation of a stable gel. The

pigments and melted waxes are added, and the mixture is mixed thoroughly. Water

and petroleum distillates are the common solvents used in mascara.

Face Powder

Face powder is a type of

pressed powder that is used to enhance the appearance of the skin of a

person. It makes the skin of a person

having dark skin appear brighter and makes the skin of a person having pale

skin appear darker. It also has the

ability to give a smooth finish, cover blemishes, absorb perspiration, and

absorb excess oil on the skin. Modern face powders do not merely consist of

cosmetic active ingredients or vitamins but are blends of other additives such

as polymers, surfactants, solvent, colorant and Rhapsody, a type of talc. These

additives are added to promote slip, adhesiveness, lubricity, and long wear.

Adhesion is the physical attraction of unlike molecules for each other.

By promoting a strong contact, adhesion works to enhance the retentive force of

the interfacial surface tension. The hydrophobic and hydrophilic behavior have

tendency to orient their long hydrocarbon chain into the non-aqueous

environment at an aqueous environment. This kind of oriented adsorption

consequently reduces the interfacial tension.

Rhapsody is the main composition used in the cosmetic products with 70-90 weights in percent in total (Rhapsody Formulation). This mineral has tendency to spread the active ingredients of the cosmetic easily and give a smooth feeling on the skin. It has excellent lubricity and skin adhesion. There are two type of Rhapsody. Each has a difference in reflectance due to the presence of different average particle sizes, based on the specification provided by the Ultra Chemical Inc. in the physical properties. The Rhapsody 2M having average particle size of 14-16 is suitable for the person having pale skin, causing the skin to appear darker, while Rhapsody 4M having average particle size of 3.0-4.5 has the opposite effect for dark skin. The typical properties for Rhapsody include a melting point of 110oC and a specify gravity close to 0.919.

Figure 1: Rhapsody reflectance and translucent compared to standard talc.

*Picture from Ultra Chemical

Inc.

Rhapsody is a new approach designed to replace

standard talc and give low translucency; this will reduce the color enhancement

overall.

In addition to promoting

slip and adherences, zinc stearate is added. This metallic stearate type of

surfactant comprises only 2.0 to 6.0 percent of total weight. It is a kind of

solid binder that dissolves in mineral oil 70 cst. Zinc stearate is a white

fine crystalline powder that helps cosmetics adhere to the skin. It has

chemical formula of

Zn (C18H35O2)2

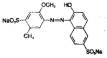

with a molecular mass of 632.3 (INCI). The following structure indicates the

zinc stearate has a long hydrocarbon chain.

This adheres the cosmetic to the skin for a longer period of time.

Figure 2 : Chemical structure of Zinc Stearate.

*Picture from VIVA Company.

The ideal physical properties

are that it is white powder, containing less than 6% moisture and having

alkaline properties with a pH ranging from 10 to 11. The melting point is in

the range of 118 to 122 oC, and the bulk density for this material

is 260 to 360 grams per liter where it is only soluble in mineral oils. The

properties of zinc stearate are use to lubricate raw beads to prevent them from

fusing together or forming lumps. This is due to the increase of the

die-filling density by promoting the powder flow ability.

Octyl palmitate is added to the formulation of long wearing pressed

powder for a person having pale skin. This is an octyl ester type of surfactant

that behaves as liquid binder. It has the same function to provide cohesion for

the cosmetic ingredients on the skin by imparting a dry, light silky feel

(Cosmetic Ester, Stepan). The forming of this alky ester is by reacting

2-ethylhexyl alcohols with palmitic acid. Palmitic acid is used as emulsifier

to promote the formation of intimate mixtures of immiscible liquids. The

chemical structure for the formation of octyl palmitate is shown below:

Figure 3: Typical Octyl Ester structure from reacting 2-ethylhexyl alcohol with palmitic

Acid.

*picture from Stepan Company

This type of octyl ester is

used to smoothen and soften the skin and is known as an emollient and a

conditioning agent. It has good qualities because it does not feel oily, thus

it is suitable to serve as a protectant and to help in replacing the natural

ester missing from older skin.

There are other relevant

ingredients that work in perfecting the cosmetic product. Coloring material

such as yellow, brown or black iron oxides (Fe2O3)

contained at approximately 0.1 to 10

percent by weight. Iron oxides are the main pigment besides other

inorganic pigments such as chrome oxide and chrome hydrate. This powder will

help in augmenting the underlying skin and foundation tones, using the

different strength of transparency for a person either having dark or pale

skin. In contrast to a small amount of iron oxide in face powder for pale skin,

there is increase of 95% when dealing with dark skin. The high colorant used

here is serving the purpose to enhance the skin shininess.

![]()

Long Wearing Pressed Powder

(for a person having pale skin and dark skin)

![]() COMPOSITION

COMPOSITION

Preferred by weight Range Components % by weight Pale skin / Dark skin

(1) Talc, Rhapsody 70.0 - 90.0 90.5 (2M) 74.5 (4M)(Filler/Matrix)

(2) Iron Oxides (Colorants) 0.1 - 10.0 0.5 15.0 (3) Polyethylene, Micronized 2.0 - 6.0 3.0 0.0

(4) Octyl Palmitate 2.0 - 8.0 6.0 0.0

(Liquid Binder) (5) Zinc Stearate 2.0 - 6.0 0.0 3.5 (Solid Binder) (6) Mineral Oil 70 cst. 2.0 - 9.0 0.0 7.0 (Liquid Binder)

Total 100.0 100.0

![]()

![]()

Table #1: The

main composition of the formulation of face powder for both the person having

pale and dark skin. *Source from Ultra Chemical Inc.(Long Wearing formulations-pale and

dark)

The qualities of the products have achieved the objective of transparent pressed powder with high lubricity and good adhesion. In addition, it exhibits prolonged wearing characteristics without overpowering the appearances on the skin, for example noticeable chalkiness.

Based on the Ultra Chemical Inc. processing procedures, the first step is to pulverize or to crush the iron oxides on equal quantities of Rhapsody talc in powder form. This mixture is then compressed into pan utilizing pressures in the range of 200 to 2000 psi.

Liquid Cream

Liquid cream makeup is

designed to cover blemishes in the skin and even skin tone and texture. In order to satisfy these design objectives,

the cream must have an even color, last all day without rubbing off, but also

be removable with cleansers that are not harsh to the skin. This is achieved through a mixture of humectants,

emulsifiers, emollients, gums, colorants, fragrance, preservatives, filler, and

matrix components.

The

main humectants used in the formulation of liquid creams are butylene glycol

and other polyols. Humectants must be

able to hold moisture at a variety of relative humidities (DeNavarre 165). This helps the cream to keep from drying out

when it is opened or balling up when it is applied to the skin (Harry Cosmetics

734). The humectant should readily

absorb moisture from the atmosphere to keep the cream from drying. However, the amount of water that the

humectant absorbs must also not change too much with changing humidity

(DeNavarre 168). This keeps the cream

from having drastically different properties as the weather changes (Harry Cosmetics

740). The humectant also functions to

moisturize the skin, plasticize the liquid cream, and control the texture

(DeNavarre 165). In the Ultra Chemical

formulation of liquid cream makeup, butylene glycol is the humectant used, at a

weight percent of 0.0 to 8.0.

Emulsifiers

are types of surfactants added to cream makeup to reduce surface and

interfacial tension between the water and oil phases (Balsam 575). They allow the oil-like components of the

cream to be stable in the water base as small droplets. Emulsifiers are large molecules such as

lecithin, polysorbate 20, stearic acid, SE glycerol mono stearate, and cetyl

alcohol (UltraChem – liquid cream), which contain both a long-chain hydrocarbon

and a polar end. This polar end may be

the COOH group of an acid, the OH group of an alcohol, or the double-bonded

oxygen of an ester (Harry Principles 259). The long hydrophobic tails trap oil droplets in them, while the

hydrophilic heads allow the molecule to be soluble in the water base (Harry Cosmetics

650). An ideal emulsifier will reduce

the surface tension between the water and oil phases enough to create a stable

emulsion. This is achieved through a

balance of the size of the long-chain hydrocarbon and the degree of

hydrophilicity of the head group. A variety

of emulsifiers are used in the Ultra Chemical formulation of liquid cream

makeup. The total weight percent of all

the emulsifiers ranges from 1.7 to 11 weight percent (UltraChem – liquid

cream).

Emollients

are used to smooth and soften the skin.

The emollients used in the Ultra Chemical formulation of liquid cream

are capric triglyceride at 1.0 to 8.0 weight percent, isopropyl myristate at

1.0 to 8.0 weight percent, and squalane at 0.0 to 5.0 weight percent (UltraChem

– liquid cream). Capric triglyceride

and isopropyl myristate are esters, formed by the reaction of an acid with an

alcohol. Squalane, in comparison, is a

long-chain hydrocarbon with the molecular formula C30H62

and a molecular weight of 422.80. It is

soluble in fixed and mineral oils, while only slightly soluble in alcohol and

acetone, due to the presence of a hydrophobic chain and no hydrophilic groups

(Harry Principles 455).

Gums

are added to the liquid cream to act as a protective colloid, suspending agent,

and film former. They are long-chain

carbohydrate polymers containing sugar units (DeNavarre 109). The gums used in the Ultra Chemical

formulation of liquid cream are hydroxethyl cellulose at a weight percent of

0.10 to 0.40 and xanthan gum at a weight percent of 0.40. Hydroxethyl cellulose is a series of

cellulose derivatives with a wide range of viscosities and solubilities. Ideal properties for gums include little

change in viscosity with pH (Harry Principles 122).

Other

chemicals that are added to the liquid cream makeup are iron oxides, titanium

dioxide, Rhapsody 4M, fragrances, and preservatives. The iron oxides and titanium dioxide are added for color, while

Rhapsody 4M is added as a filler and matrix.

Fragrances make the cream smell pleasant as opposed to like chemicals. Preservatives keep the cream usable for long

periods of time.

The complete formulation can be found in the table

below.

According to the formulation by Ultra Chemical Corporation, liquid cream makeup is created in a series of steps. First, the water base is added to a kettle and the other water-soluble ingredients are added in order. The gums and pulverized pigments are allowed to completely disperse in the water phase at 75 °C before the oil phase is added. The ingredients in the oil phase are combined at 70 °C and then added to the water phase. The entire mixture is then cooled to 35°C before the fragrances and preservatives are added. Finally, the mixture is cooled to 28°C and put into containers to be sold.

Marketing

In today’s cosmetic market, the sellers are targeting people of all ages and both genders to market their products efficiently. Advertisement is a likely approach to inform the consumer regarding new products and to persuade them to buy them because of the distinct features from others comparable cosmetic in the current market. New breakthroughs are under development, the purposes being to attract and give the opportunity for the customer to go through the product directories, compare prices and ingredients to find a type available online that suits them, and have the product shipped to their front door. The Internet is another powerful tool to send product information online without printing pamphlets. Customers visit shopping malls often during the holiday season. This is a chance to promote the company product where free samples can be given away. Experienced and trained sales personnel are required to entice the customer to buy the cosmetic products that they are promoting. Customer complaints and suggestions are a valuable asset to help cosmetic companies make improvements. In general, customer assessment through questionnaires provides information on changing requirements in both packaging and cosmetic performance.

Cost

According to ACNielsen, the market for cosmetics reached

$3.4 billion in the fiscal year ending in June of 1999. Yearly retail sales are approximately $300

million, although this number depends on the amount of disposable income. It is expected by Euromonitor International,

a global information provider (euromonitor), that sales will top $23 billion by

2003 (ecrm).

Labeling

The Food and Drug Administration regulates the labeling of cosmetics. Labels must contain a list of ingredients in descending order. Professional grade cosmetics, those designed to be used only by trained beauticians, must be labeled “For Professional Use Only.” Also, specific warnings must appear on cosmetics. For example, any flammable products must be labeled as such (cfsan-labl).

Conclusion

Beauty can be pleasing, lovely and pretty to the eye. In general, characteristics of polymers and surfactants in modifying the cosmetic adhesive properties, slip and smooth feeling, longer wearing, and more importantly reducing the allergic reaction between the cosmetic ingredients and the skin. Face powder, dry eyeshadow, and rouge ingredients consisting of zinc stearate and octyl palmitate have made a great contribution in reducing the interfacial tension and increasing the adhesiveness and the slip at the same time. The emulsifiers in liquid cream makeup, including lecithin, polysorbate 20, stearic acid, SE glycerol mono stearate, and cetyl alcohol allow emulsions of water-based ingredients and oil-based ingredients to exist. Glycerin, isopropyl myristate, and cetyl alcohol allow the same for gel-type eyeshadows, while caprylic and capric triglycerides allow such emulsions in cream-type eyeshadows and rouges.

References

http://eudrams1.is.eudra.org/F3/home.html

- European Commission

http://eudrams1.is.eudra.org/F3/inci/index.htm – INCI

http://photography.about.com/library/weekly/aa061801d.htm

http://pubs.acs.org/cen/whatstuff/stuff/7728scit2.html

http://stepex.co.uk/conference_proceedings/conference_proceedings/pcia_march2000/ emulsions_lipsticks.html

http://www.cbsc.org/alberta/search/display.cfm?Code=2248&coll=FE_FEDSBIS_E

http://vm.cfsan.fda.gov/~dms/cos-safe.html.

http://www.cfsan.fda.gov/~dms/cos-labl.html

http://www.cfsan.fda.gov/~dms/cos-lab3.html#clgl14

http://www.csmt.ewu.edu/csmt/chem/jcorkill/soapcont.html

http://www.ecrm-epps.com/Expose/V3_8/Trends_Cosmetics.asp

http://www.essentialwholesale.com/cosing.html

http://www.euromonitor.com/default.asp

http://www.pcimag.com/CDA/ArticleInformation/features/BNP_Features_Item/0,1846,13449,00.html.

http://www.sodiumstearate.com/zincstearate.htm

http://www.speakeasy.org/~mrjones/chemdesc.htm

http://www.stockideas.com/cestisa/pigments.htm

http://www.suppliercd.com/scd10/STEP0001/Attach/m0000741.pdf

http://www.ultrachem.com/formulations/lipstick.html

http://www.ultrachem.com/formulations/liqmakeup.html

http://www.ultrachem.com/formulations/pressedeyeshadow.html.

http://www.ultrachem.com/formulations/pressedpowderd.html

http://www.ultrachem.com/formulations/pressedpowderp.html

http://www.ultrachem.com/products/perservative.html.

http://www.ultrachem.com/products/petrolatum_hmps.html

http://www.ultrachem.com/products/surfactants.html

http://www.ultrachem.com/products/talc_rhapsody.html

http://www.walgreens.com/store/pickcolor.jhtml?PSID=201896&CATID=100292

http://www.walgreens.com/store/pickcolor.jhtml?PSID=200611&CATID=100566

http://www.walgreens.com/store/pickcolor.jhtml?PSID=201565&CATID=100562

http://www.walgreens.com/store/pickcolor.jhtml?PSID=200673&CATID=100566

http://www.walgreens.com/store/pickcolor.jhtml?PSID=201969&CATID=100562

http://www.walgreens.com/store/pickcolor.jhtml?PSID=201873&CATID=100292

http://www.walgreens.com/store/pickcolor.jhtml?PSID=201239&CATID=100562

Andersen, Kristin. “Cosmetic Colorants.” Healthwell. Penton Media (04 Apr 2002). http://www.healthwell.com/hnbreakthroughs/apr98/colorants.cfm.

Avon Glimmer Lights Eyeshadow (Glimmering Grape) Ingredient List (Label).

Balsam, M.S. and Edward Sagarin, eds. Cosmetics: Science and Technology: Volume 3. John Wiley and Sons: New York, 1974.

Conry, Tom. Consumer’s Guide to Cosmetics. Anchor Press/Doubleday: Garden City, N.Y., 1980.

DeNavarre, Maison G. The Chemistry and Manufacture of Cosmetics : Volume II – Cosmetic Materials. D. Van Nostrand Company, Inc.: New York, 1962.

Draelos, Zoe Diana, MD, PA. “Cosmetics.” eMedicine Journal, December 5 2001, Volume 2, Number 12. http://www.emedicine.com/derm/topic502.htm.

Harry, Ralph G. Cosmetics: Their Principles and Practices. Chemical Publishing Co., Inc.: New York, 1956.

Harry, Ralph G. The Principles and Practice of Modern Cosmetics: Volume Two – Cosmetic Materials. Chemical Publishing Co., Inc.: New York, 1963.

Marmion, Daniel M. Handbook of U.S. Colorants for Food, Drugs, and Cosmetics. 2nd Ed. John Wiley & Sons, 1984.

Maybelline D-29 Antique Olive (pearl) Eyeshadow Ingredient List (Label).

Mufti, Jabbar and Ralph Macchio. ‘R & D in the Cosmetic Age.’ January 2001.

Mufti, Jabbar. ‘A Closer Look at Innovations In the Personal Care Market.’ November 1999.

Poucher, W.A., and G.M. Howard. Perfumes, Cosmetics and Soaps. Vol. I. 8th Ed. Chapman and Hall, 1974.

Poucher, W.A., and G.M. Howard. Perfumes, Cosmetics and Soaps. Vol. III. 8th Ed. Chapman and Hall, 1974.

“Product Dictionary.” Make Me Up (2000). http://www.emakemeup.com/ingredients.html - List and short description of cosmetic ingredients

Rieger, Martin M. Surfactants in Cosmetics. Dekker: New York, 1985.

Sagarin, Edward, Ed. Cosmetics: Science and Technology. Interscience Publishers, 1957.