I. Introduction

A.

The

History of Tires

The wheel is one of the greatest inventions

in human history due to its wide range of applications. These applications include any type of

transportation; whether it is people, materials, or equipment being moved. Charles Goodyear invented the first rubber

tires in 1839. Before the advent of

these tires, riding in a car was very uncomfortable due to the rough ride.

In 1830,

Goodyear wanted to develop a rubber product that was useable by the general

public. To carry out his experiments,

Goodyear bought a truckload of raw rubber from a shoe factory and attempted to

turn it into a complete solid. His

experiments were halted, when he was sent to prison for not paying his debt

from the rubber purchase 1.

This set back did not stop Goodyear.

While in debtor’s prison, Goodyear continued his experiments with the

raw rubber and when he was released from jail, the product he was making had

the consistency of gum. This rubber

material was called natural or India rubber. Goodyear did not stop there with his

experiments. He discovered that he was

able to harden the rubber by mixing the rubber with sulfur and then treating it

with an acid gas. The rubber ball was

tossed around and it accidentally landed on top of a hot stove. To the surprise of Goodyear, the rubber

began to change phase and melt, instead of scorching. However, when Goodyear attempted to scrape the rubber off the

stove, he discovered it had hardened to the consistency that he was trying to

achieve 1. With the

discovery of vulcanization, and the beginning of the industrial revolution in

both Europe and North America, the tire evolved from a rubberized canvas

protecting a rubber tube to a complex fabric, steel and elastomeric composition

21,22.

B.

Biography

of Charles Goodyear (1800-1860)

Goodyear

was born in New Haven, Connecticut on December 29, 1800. With no formal education, he

entered the hardware business

with his father as a partner in 1821 but later failed and was bankrupt in 1830. Thereafter he turned his talents to the

commercial improvement of India rubber, which, until his time was not used much

in industry because of the adhesiveness of the surface and because of its

inability to withstand temperature extremes 21. Goodyear began making rubber goods in the

fall of 1933, and the material sold for a fairly good price. Unfortunately, this rubber was not perfect. During the summer of 1934, the rubber melted

because of the heat and developed and offensive odor. Over twenty thousand dollars worth of products were returned to

him and the company 21.

Goodyear,

then went on to develop a nitric acid treatment to eliminate some of the rubber

defects and in 1837, he negotiated a contract in which he made mailbags for the

U.S. Government. The rubber fabric for

the mailbags was not much more successful and proved unsuitable at higher

temperatures. Goodyear later became

acquainted with Nathaniel Hayward, who was a foreman at a company called the

Eagle Company, where he had used sulfur in solvents to permeate the

rubber. The two men worked together and

made life preservers by the use of sulfurous acid gas and the solarizing

process which is the exposure of rubber sheeting to sulfur dioxide and then to

the sun’s rays. The next year, Goodyear

bought this patent from his partner 22.

Goodyear

continued his research for the means to make a better from of rubber without

the stickiness. He discovered that

rubber was charred and not melted by boiler sulfur. The famous vulcanizing process was discovered and was later

patented in 1844. Vulcanization was to

revolutionize the rubber industry.

Sadly, Goodyear was not much of a businessman and was unable to profit

financially from his discovery. He died

a poor man on July 1, 1860 and six of his twelve children also eventually died

from diseases brought on by the Goodyear family's persistent poverty. Charles Goodyear never saw a penny of the

earnings from Goodyear Tire & Rubber Co. since the company was formed

nearly 40 years after his death 21.

II. Tire Production

A.

Tire

Statistics

Some key tire production statistics for 1998-1999 are given in the following table 13,14:

B.

Raw

Materials

In order to manufacture a tire the major raw

materials required are: fabric (steel, polyester, nylon, or combinations

of these), rubber (synthetic and natural types: hundreds of different

types of polymers), reinforcing chemicals (carbon black, silica,

resins), anti-degradants (ozonants, paraffin waxes), adhesion

promoters (cobalt salts, brass on wire, resins on fabric), curatives

(cure accelerators, activators, sulfur), and processing oils (oils,

tackifiers, softners) 14,15.

C. Processing & Production

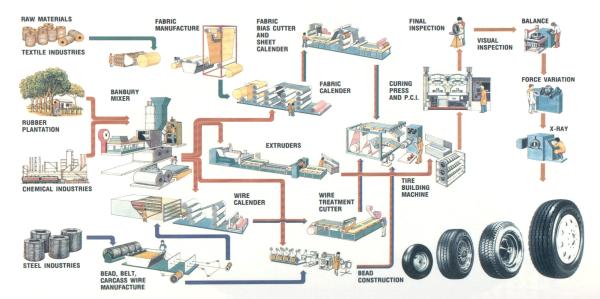

The tire making

process (see schematic below) starts by mixing different varieties of rubber

with process oils, carbon black, pigments, antioxidants, accelerators and other

additives, each of which contributes certain properties to the compound 13.

Figure 1: Schematic of the Tire Production Process

These ingredients

are mixed in giant blenders (called banbury mixers) under tremendous heat and

pressure. The ingredients are blended together into a hot, black gummy compound

that will be milled. The cooled rubber

takes several forms. Most often it is processed into carefully identified slabs

that will be transported to breakdown mills. These mills feed the rubber

between massive pairs of rollers, repeatedly feeding, mixing and blending to

prepare the different compounds for the feed mills, where they are slit into

strips and carried by conveyor belts to become sidewalls, treads or other parts

of the tire.

Still another

kind of rubber coats the fabric that will be used to make up the tire's

body. The fabrics come in huge rolls, and they are as specialized and critical

as the rubber blends. Many kinds of fabrics are used: (i.e. polyester or

nylon). Most of today’s passenger tires have polyester cord bodies.

Another component

called a bead, shaped like a hoop. It is made of high-tensile steel

wire, which will fit against the vehicle's wheel rim. The strands are aligned

into a ribbon coated with rubber for adhesion, then wound into loops that are

then wrapped together to secure them until they are assembled with the rest of

the tire.

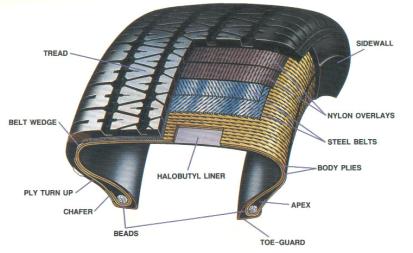

Radial tires are

built on one or two tire machines. The tire starts with a double layer of

synthetic gum rubber called an inner liner that will seal in air and

make the tire tubeless. Next come two

layers of ply fabric, the cords. Two strips called apexes stiffen

the area just above the bead. Next, a pair of chafer strips is added, so

called because they resist chafing from the wheel rim when mounted on a

car. The tire building machine

pre-shapes radial tires into a form very close to their final dimension to make

sure the many components are in proper position before the tire goes into the

mold.

Now the tire

builder adds the steel belts that resist punctures and hold the tread

firmly against the road. The tread is the last part to go on the tire. After

automatic rollers press all the parts firmly together, the radial tire, now

called a green tire, is ready for inspection and curing.

The curing

press is where tires get their final shape and tread pattern. Hot molds shape

and vulcanize the tire. The molds are engraved with the tread pattern,

the sidewall markings of the manufacturer and those required by law. Tires

are cured at about 300 oF for 12 to 25 minutes, depending on their

size. The tires are popped from their molds and taken to final finish and

inspection. If anything is wrong with the tire, it should be rejected. An inspector’s trained eyes and hands catch

some flaws; specialized machines find others 14, 15, 17.

Some tires are

pulled from the production line and X-rayed to detect any hidden

weaknesses or internal failures. Also, quality control engineers regularly cut

apart randomly chosen tires and study every detail of their construction that

affects performance, ride or safety 17.

Figure 2: Cross-Section

D.

The

Chemistry of Tires

Introduction

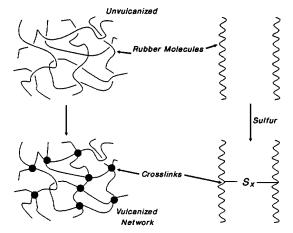

Vulcanization, or the process by which rubber is heated with sulfur to create a network of chemical cross-links, was invented by Charles Goodyear in 1839. It produces a finished product that is not sticky like raw rubber, does not harden with cold or soften much except with great heat, is elastic, springing back into shape when deformed instead of remaining deformed as unvulcanized rubber does, is highly resistant to abrasion. The process, a key advancement during its time, has been refined and enhanced since 2.

Natural rubber, also known as isoprene, when

vulcanized will form a three dimensional network of mono-, di-, and polysulfide

bridges which give the rubber its characteristic strength and elasticity. It is

also important to note that the cross-links that give the tires these

properties are not just sulfide linkages.

They can be ionic clusters, polyvalent organic clusters, or polyvalent

metallic ions. The process increases retractile force of the material, while

decreasing the amount of permanent deformation occurring with the removal of a

load 2.

The other major chemical process associated

with tire manufacturing is the process by which brass is coated onto the steel

belts, which are used in tire reinforcement.

The brass coating adheres better to the rubber, and also helps to

increase the retractile force of the composite material 1, 2.

Vulcanization

The process of vulcanization profoundly

changes the molecular structure of rubber, with the average distance, in terms

of molecular weight, between linkages being approximately 4000-10000. Hard

rubber is vulcanized rubber in which 30 – 50 % sulfur has been mixed before

heating; soft rubber contains usually less than 5 % sulfur. After the sulfur

and rubber (and usually an organic accelerator) are mixed, the compound is usually

placed in a mold and subjected to heat and extreme pressure A vulcanized

material cannot be processed in an extruder, mixer, or any device, which

requires the material to flow.

Therefore, the vulcanization is done after the material has taken its final

shape or form 1,14.

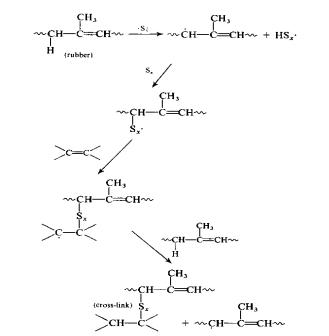

Figure

3: Sulfide

Network Formation

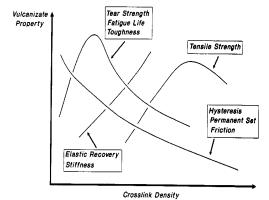

The characterization of polymers

starts with certain properties such as hysteresis, tear strength and tensile

strength all of which can be plotted as a function of cross-link density within

the polymer. This is shown in the

figure below:

Figure

4: Vulcanizate Properties as Function of Cross Link

Density

Hysteresis represents the history

dependence of physical systems. If you push on something, it will yield: when

you release, does it spring back completely? If it does not, it is exhibiting

hysteresis, in some sense. In the

figure above, hysteresis decreases with increasing cross-links. This is because the cross-links give the

material some strength and rigidity, which allow it to return to its original

shape when the loading is relieved. A

material with no cross-links would remain permanently deformed 2.

There exist many types of vulcanization:

with and without accelerator, phenolic curatives, benzoquinone derivatives,

metal oxide, organic peroxide, and dynamic.

This report will focus mainly on the chemistry of vulcanization with and

without accelerators 2.

Vulcanization without the use of an

accelerator was commonplace until 1906 when Oenslager found the first useful

accelerator (aniline) for use in the process.

The unaccelerated process utilized elemental sulfur at 8 parts per 100

parts of rubber (phr) and required a temperature of 140 oC for 5

hours. The common reaction mechanism

for unaccelerated vulcanization is the free-radical method, given below 1,2:

Figure

5:

Unacclerated Vulcanization Mechanism via Free-Radical Polymerization

The reaction is a basic free-radical

polymerization between isoprene and a sulfur radical. Since this scheme has a long curing time, it is not practical for

use in designing a mass-production plant around. As discussed in the next section, accelerators can greatly

increase the rate of reaction (hence, the name accelerator) and thus

unaccelerated vulcanization is generally not used except for certain specialty

products.

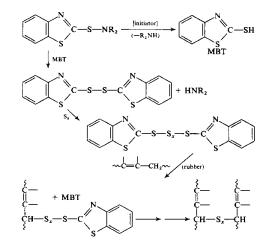

Accelerated vulcanization, however,

can perform the same operation listed above at the same temperature with an

elemental sulfur concentration of 0.5 phr and decrease the reaction time to as

low as 1 to 3 minutes 2. The

main mechanism for accelerated vulcanization is listed below:

Figure

6: Mechanism

for Accelerated Vulcanization

Where MBT (2-Mercaptobenzothiazole) is the

accelerator for the reaction. MBT acts

as an initiator by removing the –R-NH2 group from the material allowing

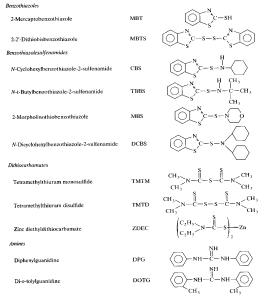

it to react with itself quicker. A list

of common accelerators is given in the figure below. The most important of which is MBT, which replaced the toxic

aniline in 1925. MBT reacts as shown

above with the sulfur, thus allowing it to react even faster with the rubber

than the elemental sulfur 1.

Figure

7: Different

Types of Accelerators for Vulcanization

The accelerators given above can be

used in a variety of roles to either increase the rate of linkage formation, or

the extent of formation (di-, tri-, poly-linkages, etc.).

Brass Wire

Adhesion

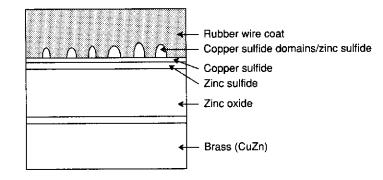

The second area of importance is the

brass-coating placed on steel belts for adhesion to the melted rubber. Since carbon steel has a poor affinity for

vulcanized rubber, the overall strength of the tire is reduced. Therefore, brass (CuZn) is deposited on the

surface of the steel belts so that a stronger bond between the steel and rubber

can be formed. As the rubber flows

around the steel belts in the mold, a thin copper sulfide (CuS) layer is formed

on the surface of the steel belts.

Since the layer is porous, the rubber begins to move into the

layer. When the vulcanization process

is started, the rubber forms cross-links not only with itself, but with the CuS

also, resulting in very strong attractions.

The entanglements between the rubber and CuS layer help form a powerful

bond between the rubber and steel. This

process is diagramed below 1, 2:

The formation of these domains

creates a considerable adhesive force between the 2 materials, and is necessary

for the long-term durability and strength of the material. A problem with this process is that the

presence of either zinc/iron sulfides (ZnS/FeS) will inhibit the process. Neither of these materials exhibits the

porosity that CuS does, therefore the entanglements that form the strong bonds

do not occur, resulting in weak surface adhesion. Also, the presence of Zn2+ will corrode the rubber

because it will form either ZnO or ZnOH will accumulate in the CuS layer and

will displace the disulfide linkages.

This can be prevented by doping the brass with small amounts of

trivalent cobalt 1, 2.

E.

Disposal

and Recycling of Used Tires

Today, a variety of recycling

techniques encourage the use of tires at the end of their lifetime. They can be

used for energy production as a fuel, especially in cement works. Or the

materials can be re-used, for example by transforming the tire into a powder

which is used for flooring materials, for making rubber objects or in the

manufacture of new tires 13, 12.

Some

statistics on tire recycling are given below.

These statistics are for retreaded-tire usage in 2000 11:

- ~ 27.7

million retreaded tires were sold in North America in 1999

- ~ 600

million lbs. of tread rubber used (recycled) by the North American retread

industry

- Almost all

of the world’s commercial airlines use retreaded tires

- Cost of a

retreaded tire is ~ 30-50 % lower than that of a new tire, with same

performance

- Retreading

conserves millions of gallons of oil each year (each new passenger tire

made from 7 gallons of oil vs. 2 gallons for a retreaded tire)

III. Tread Separation Problem Overview

A.

Suspicion

of a Problem

The safety of sport utility vehicles has

always been an issue for the general public.

Complaints include: excessive gasoline consumption, and overbearing size

of the vehicles on the road. In late

July 2000, authorities noticed that sports utility vehicles had a tendency to

tip over, and this observation was especially prevalent in regard to the Ford

Explorer models. The initial

explanation many came up with was that the vehicles were too large and that

their center of gravity was higher compared to other SUV’s. After further investigation from the

National Highway Transportation Safety Administration (NHTSA), the agency

noticed that all rollover accidents involving the ford explorer had one thing

in common; they all had the same tires.

The tires that were used on those vehicles were the Firestone ATX, ATX

II and Wilderness AT tires. The agency

also noticed that in most of the accidents, the tires were damaged in such a

way that the tread was completely separated from the radial 3,7.

B.

Cause

of Problem

After several months of investigation, which involved cutting apart over 850 tires and examining more than 2,500 recalled tires; the Bridgestone/Firestone Corporation believed that they had an idea as to what was going wrong. The tire manufacturers believed that there were four major factors that resulted in the increased rate of accidents 4, 5:

1. The Ford Motor Company

2. The drivers of the vehicle(s)

3. The tread design

4. The adhesiveness to the steel belts

Bridgestone/Firestone admitted that part of

the problem was due to their design, but the company also blamed the Ford Motor

Company, as well as the drivers for the accidents. Since most of the tires were installed as original equipment on

Ford Explorers, Bridgestone/Firestone asserted that Ford designed and built the

vehicles too heavy for the tires. Also,

Bridgestone/Firestone claimed that the tire pressure recommended by Ford, 26

psi, was too low and that the recommended tire pressure should have been

approximately 30 to 35 psi. Ford

maintains that their vehicles were properly designed, and do not in any way,

contribute to the tire tread separation 4,8.

Bridgestone/Firestone believed that the

second factor contributing to the failure of the tires was inadequate consumer

maintenance. They stated that the tires

should have been accurately inflated, which would have reduced the possibility

of the tire heating-up, therefore preventing the tread separation.

Finally, investigators found that there was a problem with the tread design in the ATX tires. The problem with the tread design involved the shoulder pocket of the tire, which is the interface between the wall of the tire and the tread. The poor design of the tread caused the tires to prematurely, and more profoundly than other tires. However, the tread design was not the only design problem with the tires. Problems with the rubber adhesion to the steel belts also were a cursory cause of the tread separation. This problem was confined to the tires that were made and manufactured in the plant in Decatur, Illinois 7.

C.

‘Weak

Link’ in Tires

Although there are many causes as to why the

treads separated, the main cause for the accidents was the design of the tire

itself. With the added stress and other

factors to the tires, the design was not able to withstand the actual

conditions. Tire

manufacturers know that a leading cause of tread separation is due to the

design and placements of the belts and overlying tread. Also, tread and belt separations can occur

due to poor adhesion of the components from the use of old and

expired adhesives, improper temperatures, rust, unclean manufacturing

facility, moisture, oxidation, grease, and particulate matter. Many former and current employees of the

Decatur Firestone plant have told reporters and/or lawyers about how poor the

quality control is at that plant. Joe

Roundtree, a former employee of Firestone told Dateline News that, “there were

times when rubber, which had been tagged as rejected earlier in the day would

be used anyways when supplies ran short”.

Roundtree also noted that a tool called an awl (used for a variety of

jobs, often in the early stages of construction, to release pockets of air

trapped in between layers of the tires) was being used in the post-processing

of the tires. Also, other employees

from the Decatur plant have testified that Firestone told their employees to

puncture bubbles in order to cover flaws and also the poor quality control in

the keeping of steel-belts 9.

Of

all of the known problems resulting in tire tread and belt separation, the

leading cause of tread separation is the poor adhesion between the rubber and

the steel. The method used most often

involves plating the metal with brass and to apply a rubber

compound containing sulfur. If the sulfur and other compounds are not

to the correct mixture, then incomplete adhesion occurs. Also if the

brass plating is allowed to oxidize, then adhesion will not occur

properly. If there was a luster to the

belts, then most probably they were not properly coated with brass, or properly

kept 11.

Another

well know design defect, is not including an extra nylon cap belt to

encapsulate the underlying belts and bond them to the outer

core. This nylon cap belt is

placed between the top belt and the outside tire tread, therefore in a sense

capping the inner belts to the outer core to prevent the spread or

movement to the belt edge. This extra

belt was a missing

component in the Firestone ATX, Firestone ATX II and the most of the Wilderness

AT tires subject to the Firestone recall.

Had Firestone elected to use this extra cap belt, many experts believe

the numbers of tread separations would have been dramatically reduced. Firestone

had no legitimate excuse for excluding this important safety feature.

IV. Lawsuit Against Firestone and Ford Motor Co.

A.

Litigation

Pending

Both Firestone and Ford are in an ongoing battle with the public, both in terms of litigation and reputation. Many who have been in an accident or lost a family member due to a tread separation and/or rollover, have filed individual and class action lawsuits against Ford and Firestone. Thus far, most of the cases have been settled out of court and a class action lawsuit remains. One of the first major lawsuits brought against Firestone ended up in a favorable judgment for the plaintiff -- 90 million dollars in damages 8.

B.

Firestone’s

Position on the Issue

Bridgestone/Firestone have taken responsibility for the faulty

design in their tires. They have

initiated a worldwide recall of the faulty tires and have offered their

customers new tires, free of charge, to replace the defective ones. Firestone has also gone ahead and began to

test their other tires for the same problem, and modify any that require doing

so. Although Firestone has acknowledged

the mistakes in their design, they do not believe that the blame should be

placed wholly on them. They believe

that the design parameters of SUV’s (such as the height and size of the

vehicle) and the drivers/driving conditions are to blame for this unfortunate

tragedy 13, 18.

C.

Ford

Motor Corporation’s Position

Ford Motor Corporation, still vehemently stands by the design of their Explorer series SUV’s, and deny any accusations that blame them for the accidents. Their argument has recently been bolstered, as a jury in Texas found the company not responsible for a rollover that occurred in a Ford Explorer. The company, however, has stated that they will investigate their recommendation of 26 psi versus the Firestone recommended 30-35 psi 9, 3.

D.

Plaintiff’s

Position on Issue

Many of the victims have filed lawsuits against both companies to settle for appropriate damages in their respective cases. The main action of the plaintiff’s and their supporters for the moment has been a boycott of both Ford and Firestone products. The boycott of Firestone has had a much more profound impact on Firestone than Ford, with Ford still maintaining sales of their other top selling vehicles. Firestone, on the other hand, is suffering one of their biggest losses in company history and may be forced out of business within a year, according to some analysts 5.

V. Conclusion

At first glance, one might blame the

Bridgestone/Firestone Corporation for the tread separations in their tires

since they manufactured the defective tires.

But further investigations show that the tire manufacturing company is

just one of many factors that could have potentially prevented this from

happening. No significant person, or

company is at blame at this moment as further investigations continue. While investigations continue, lawsuits

pending are finally brought to an end with settlements settle out of

court. A mistake, simple, yet

correctable, has caused Firestone to pay millions in damages to the victims and

could cause the shut of the company.

Works Cited

1.

Alliger, G. et. al. Vulcanization of Elastomers –

Principles and Practice of Vulcanization of Commercial Rubbers. Reinhold Publishing; New York, NY: 1964.

2.

Mark, James E. et. al. Science

and Technology of Rubber – Second Edition. Academic Press; San Diego, CA:

1994.

Specific Websites:

3. Reuters: http://www.cnn.com/2001/WORLD/asiapcf/east/02/22/japan.bridgestone/index.html

4. Candiotti, Susan: http://www.cnn.com/2001/LAW/01/08/firestone.settlement.bus.01/index.html

5. Candiotti, Susan: http://www.cnn.com/2001/LAW/01/08/firestone.01/index.html

6. Garsten, Edward: http://www.cnn.com/2000/US/12/21/firestone.nhtsa/index.html

7. Candiotti, Susan: http://www.cnn.com/2000/LAW/10/27/firestone.depositions.bus/index.html

8.

AP: http://cnnfn.cnn.com/2000/09/11/companies/bridgestone/

9. AP:

http://www.msnbc.com/news/484123.asp

10. N/A: http://www.michelin-us.com/us/eng/tire/guide/index.html

11.

N/A: http://www.itra.com/ind_info.html

12. Rubber Manufacturers Association: http://www.rma.org/publications/pdf/mis_demo_mtr.pdf

13.

http://www.rubbernews.com/subscriber/charts/global.html

14. http://www.goodyear.com/us/products.html

15. http://www.bridgestone-firestone.com

16. http://www.nhsta.dot.gov/hot/firestone/indes.html

17. http://www.howstuffworks/com/tire1.htm

19. http://www.firestone-tire-recall.com

20. http://www.tire-defects.com/Default.htm

21.

http://www.invent.org/book/book-text/47.html

22. http://www.goodyear.com/us/corporate/strange.html