Colloidal and surface phenomenal aspects of Ice cream

Yusuo Bob Chang

Joseph Kuechle

Travis Reese

Pierre SaintLouis

April 9, 2002

Table of Contents

I.

Introduction - 3

II.

History - 4

III.

Design Considerations - 6

IV.

Main components and composition - 9

V. Basic structure of Ice cream - 10

VI. Ingredients contributing to - 11

physical properties

VII.

Processing and Manufacture - 24

VIII.

Marketing Considerations - 31

IX.

Suppliers - 36

X.

Conclusion - 37

XI. References - 38

I. INTRODUCTION

Homogenized dairy emulsions such as ice cream are generally colloids containing fat droplets as the dispersed phase. Ice cream is a complex food colloid in that the mix emulsion is subsequently foamed, creating a dispersed phase of air bubbles, and is frozen, forming another dispersed phase of ice crystals. Air bubbles and ice crystals are usually in the range of 20 – 50 micrometers in size. The serum phase consists of the unadsorbed casein micelles in suspension in a freeze-concentrated solution of sugars, unadsorbed whey proteins, salts and high molecular mass polysaccharides. In addition, the partially-crystalline fat phase at refrigerated temperatures undergoes partial coalescence during the concomitant whipping and freezing process, resulting in a network of agglomerated fat, which partially surrounds the air bubbles and gives rise to a solid-like structure. Various steps in the manufacturing process, including pasteurization, homogenization, ageing, freezing and hardening, contribute to the development of this structure. This paper discusses the history, design considerations, components, structure, colloidal aspects and contributing elements, processing, and marketing considerations of ice cream.

II. HISTORY

Very little is known of the early history of ice cream. It is known however, to have been introduced from Europe. The origins of ice cream can be traced back to the 4th century B.C. The Roman emperor Nero ordered ice to be brought from the mountains and combined with fruit toppings. During China's Tang period (A.D. 618-97) King Tang of Shang had a method of creating ice and milk concoctions. It is thought that ice cream was brought from China back to Europe. Over time, recipes for ices, sherbets, and milk ices evolved and were served in the fashionable Italian and French royal courts.

After the dessert was imported to the United States, it was served by some famous Americans including George Washington, Thomas Jefferson, and Dolley Madison. In 1700, Governor Bladen of Maryland was recorded as having served ice cream to his guests. A London caterer named Phillip Lenzi announced in a New York newspaper that he would be offering for sale various confections, including ice cream in 1774. The first ice cream parlor in America opened in New York City in 1776.

In the early years of ice cream, salt was mixed with ice to lower and control the temperature of the mix. The invention of the wooden bucket freezer with rotary paddles facilitated its manufacture. It was in 1832 that Augustus Jackson, a confectioner from Philadelphia, invented an ice cream recipe and a method for manufacturing it. In 1843, New England housewife Nancy Johnson invented the hand-cranked ice cream churn. She patented her invention but lacked the resources to make and market the churn herself. Mrs. Johnson sold the patent for $200 to a Philadelphia kitchen wholesaler who, by 1847, made enough freezers to satisfy the high demand. From 1847 to 1877, more than 70 improvements to ice cream churns were patented. The first large-scale commercial ice cream plant was established in Baltimore in 1851 by Jacob Fussell.

III. DESIGN

CONSIDERATIONS

Taste, texture, body, coloring, addition of fruits and candies, melt resistance, rigidity, and malleability are some of the qualities that a consumer looks for in a good ice cream. Most of these properties can be manipulated through the use of stabilizers and emulsifiers.

The flavor of the ice cream is probably its most important quality. Flavor is manipulated through the use of sweeteners, corn syrup, natural and artificial flavors. Flavor defects can be classified according to, the flavoring system (lacks flavor or too high flavor, unnatural flavor), the sweetening system (lacks sweetness or too sweet), processing related flavor defects (cooked), dairy ingredient flavor defects (acid, salty, old ingredient, oxidized/metallic, rancid, or whey flavors), and others (storage/absorbed).

A quality ice cream needs to possess a smooth and creamy texture, which is influenced by size, distribution, shape and number of ice crystals. Ice crystals give the product a course, icy texture. Ice crystals are usually formed when the product goes through “heat shock” or the temperature fluctuations experienced from storage and distribution. The amount and size of ice crystals is influenced by the use of stabilizers, addition of the right amount of solids, freezing and hardening time, and the incorporation of air and temperature fluctuations. Fluffy and sandy textures are also characteristics that should be avoided. A fluffy texture is characterized as spongy and is caused by the incorporation of large amount of air as large air cells, low total solids and low stabilizer content. A sandy texture is one of the most objectionable texture defects but easiest to detect. It is caused by lactose crystals, which do not dissolve readily and produce a rough or gritty sensation in the mouth. This can be distinguished from "iciness" because the lactose crystals do not melt in ones mouth. This defect can be prevented by many of the same factors that inhibit iciness.

A crumbly, gummy or

weak body must be avoided to produce a quality ice cream. A crumbly body is characterized as flaky

or snowy and may be caused by low amounts of stabilizer and emulsifier, low

total solids or course air cells. A gummy defect is the opposite of crumbly in

that it imparts a pasty or putty-like body. It is also influenced by the amount

and quality of stabilizer. Ice cream

that lacks "chewiness", melts quickly into a watery liquid and gives

impression of lacking richness is referred to as having a weak body. A weak

body may be caused by low solids and insufficient stabilizer.

Ice cream does not only need to withstand temperature fluctuations but also needs to have good melting characteristics. A slow, smooth meltdown is what is desired but if not processed and designed correctly the ice cream product may exhibit curdy or wheying melt down characteristics. A curdy melt down is due to the coagulation of the milk proteins and is affected by factors which influence protein stability such as, high acidity, salt balance, high homogenizing pressures, and over-freezing in the freezer. Wheying off is effected by the salt balance, protein composition, and carrageenan addition. If the ice cream does not melt, the following factors are held responsible: over emulsification, wrong emulsifier, high fat, excessive fat clumping in the mix, freezing to too low a temperature at freezer.

A manufacturer of ice cream tries to produce a product with an appealing, uniform color to it. Problems arise when ice cream exhibits an uneven and unnatural color. Uneven coloring usually applies to ice cream in which color has added, but may be noticed in vanilla ice cream under some circumstances. Unnatural colors arise when a wrong shade of color used for a flavored ice cream, too much yellow coloring used in vanilla ice cream, or when neutralization causes a grayish color.

Shrinkage is a very troublesome defect in ice cream since there appears to be no single cause or remedy. Defects show up in hardened ice cream and manifest themselves in reduced volume of ice cream in the container usually by pulling away from the top and/or sides of container. Structurally, it is caused by a loss of spherical air bubbles and formation of continuous air channels. Some factors believed associated with the defect are: freezing and hardening at ultra low temperatures, storage temperature, excessive overruns, pressure changes.

In recent years, there has been a higher demand for the inclusion of candies and fruit in ice cream. Ice cream inclusions can come in two different forms: pieces or variegates. Pieces range from small flecks of vanilla bean to partial or whole bite-size pieces of material like fruits and nuts. Variegates often are used instead of, or in addition to, pieces. In the finished ice cream, variegates appear as a ribbon. These inclusions make for more difficult processing. Not just any candy bar can just be added to ice cream; the ingredient impacts the properties of the ice cream itself and often times the freezing process changes the ingredient.

IV.

Main components and composition

Ice cream contains five main typical ingredients: milk, stabilizers, emulsifiers, sweeteners and water. Sweeteners are obviously used to enhance the sweetness of the frozen treat. Milk consists of milk fats and milk solids. In North America, fats are generally derived from milk whereas in other parts of the world, fats are more commonly derived from non-dairy sources. The milk solid non-fats contain lactose, casein, micelles, whey proteins, minerals (ash), vitamins, acids, enzymes, and gases of the milk or milk products from which they were derived.

Stabilizers are present in ice cream to produce smoothness in body and texture, retard or reduce ice and lactose crystal growth during storage and provide uniformity to the product and resistance to melting. Emulsifiers are sometimes integrated with stabilizers, but they function to improve the whipping quality of the mix, produce a drier ice cream to facilitate molding for various ice cream styles, provide smoother body and texture in the final product and give the product good standup properties and melt resistance.

The percent compositions of the ingredients are summarized in the table below.

|

Component |

Range (%) |

|

Milkfat |

10-16% |

|

Milk

Solids-not-fat |

9-12% |

|

Sucrose |

9-12% |

|

Corn

Syrup Solids |

4-6% |

|

Stabilizers/Emulsifiers |

0-0.5% |

|

Total

Solids |

36-45% |

|

Water |

55-64 |

V.

BASIC STRUCTURE

The complex physical structure of ice cream presents a challenge for food chemists, who readily concede it’s not fully understood. Despite this, food products designers know how to manipulate these structures, creating a wide variety of products packing consumer appeal.

Water, ice, air, sugar, milk fat and milk protein can be assembled into innumerable combinations, each with unique physical chemistry. Ice cream’s sensory attributes, particularly mouth-feel, dictate that ingredient and processing variables in its production strive for as much homogeneity as possible, even though ice cream is far from homogeneous.

Simply stated, ice cream’s overall design goal is: incorporating several different insoluble (air bubbles, ice crystals, and fat globules) into an aqueous phase at the smallest sizes, and in the greatest numbers, possible. One gram of ice cream of typical composition contains 1.5 x 1012 fat globules of average diameter 1µm that have a surface area of greater than 1 square meter (in a gram!), 8 x 106 air bubbles of average diameter 70 µm with a surface area of 0.1 sq. m., and 8 x 106 ice crystals of average diameter 50 µm with a surface area of another 0.1 sq. m. The importance of surface chemistry becomes obvious!

VI.

Ingredients contributing to physical properties as colloids on a molecular

To

create an ice cream product with properties meeting customer expectations, each

element of it must contribute to its properties. Not only the properties of the

ingredients alone contribute to such a product but the ingredients as they

interact in a colloidal system also play a great role in shaping these

attributes.

To

create an ice cream product with properties meeting customer expectations, each

element of it must contribute to its properties. Not only the properties of the

ingredients alone contribute to such a product but the ingredients as they

interact in a colloidal system also play a great role in shaping these

attributes.

Fat and Water

The most abundant components in ice cream are the most important. These are water and fat. The interaction between the fat and water themselves is not what is unique about ice cream but it is the manipulation of this interaction that provides the qualities of ice cream.

Fat, also known as a triacylglycerol, is large in molecular weight. The fat molecule is made up of three fatty acids bound to a glycerol molecule. This molecule is mostly non-polar and very large in weight. It adheres to itself through Vanderwaals interactions implying relatively large cohesive properties. Due to the relatively saturated nature of the molecules with single bonds in milk, as well as the low temperatures they are kept at, they tend to be more solid like than in other types of foods that use unsaturated fatty acids. This is necessary to maintain the rigidity of the ice cream. The triglycerides in milk fat have a wide melting range around +400C, and thus there is always a combination of liquid and crystalline fat. The fat used from milk is also important to ice cream due to the fact that it increases the richness of flavor in ice cream. It produces a characteristic smooth texture by lubricating the palate. The disadvantages in use of milk fat as a component include high cost, hindered whipping ability, excessive richness in flavor, and high calorie value. The best source of milk fat in ice cream for high quality flavor is fresh sweet cream from fresh sweet milk. Duplicating the fat used in ice cream from other sources of fat is difficult.

Water is a low molecular weight polar substance with high cohesive properties due to its ability to hydrogen bond. What becomes created when a mixture of the proportions of fat and water used here is an emulsion. Here there is a dispersed phase of fat in a water environment. The proportions are generally such that Phi < 0.3. Phi is known as the Low internal-phase ratio (LIPR) where Phi = Vi / (Vi + Ve) where Vi = volume of internal phase and Ve = volume of external phase.

These fats have a much lower affinity towards the water than it does for itself. This leads to hydrophobic interactions, which promotes agglomeration of the fats. They also are less dense than water and tend to float. These fats have a low solubility in water yielding to a phase separation of 14% w/w. The dispersed phase droplet size ranges from 0.1 - 10 µm.

In ice cream the fat is mechanically dispersed. However, the emulsions are unstable because the hydrophobic interactions described above, and has a tendency to drive the system to flocculate. It is this ability that the fat has to recombine that leads to a network of fat globules. It is promoted by the fact that the fat globules have a decreased diffusion characteristic as colloids as opposed to individual molecules in the frozen water. Also, they have a large surface to volume ratio, which naturally leads to this type of network formation as opposed to large globules. At the temperature below freezing the fat partially crystallizes and its crystallinity also aids in this phenomenon. This partial coalescence or network formation is an irreversible agglomeration of the fat globules. They come together in a shear field as a result of whipping. It is the crystals at the surface of the droplets that are thought to induce the connection. In partial coalescence there is a maintenance of identity of individual globules as long as the crystal structure is maintained. This means that when the crystals melt, the cluster will eventually coalesces.

Emulsifiers

This layer between the water and fat is further modified by the use of amphiphilic molecules that change the interfacial energies. These molecules alter the concentration of hydrophobic groups at the interface. Typical interfacial tensions in the ice cream system range from 15 to 25 dynes / cm. When an amphiphilic (containing hydrophilic and hydrophobic ends) emulsifying agent is added to an emulsion system, the emulsifiers concentrate at the lipid-water interface and lead to a reduction in interfacial tension to less than 10 dynes / cm. The polar, hydrophilic end decreases the amount of hydrophobic chains at the interface. There is also an ionic requirement of emulsifying agents. An emulsion system needs to be electrically neutral to maintain a stable colloid or else ionic interactions will draw the molecules together. The fat tissue in ice cream is not ionic but there are ions in the matrix and dissolved in the fats. Ionic surfactants are added to the surface of droplets and establish an electric double layer in the aqueous phase stabilizing the emulsion. These emulsifying agents increase the amount of fat globules effecting fat network and stabilize the emulsion.

An additional effect of these emulsifying agents is the fact that their addition leads to an influx of protein molecules into the serum phase during cold aging. The proteins tend to adsorb to the fat serum interface and increases the concentration in the serum from the fat. This change destabilizes the fat globules by decreasing the protein steric stabilization. This will be addressed in the section considering the proteins.

Before the freezing step emulsifiers decrease the ability of the fat to coalesce, which would happen naturally due to the energy involved. During the freezing step they add to the partial destabilization of the lipid phase. During whipping, the emulsifier causes the fat globules to agglomerate and form a network in the continuous water phase between air bubbles. As a result, air cells are stabilized and stiffness of the foam can be enhanced.

Foam is the second colloidal phase of ice cream with air and liquids being mixed. The interfacial energy between the fat and air with emulsifiers added is lower than the water/ fat interface forcing the fat more into the air. This assists in the development of a good aeration and fat distribution to maintain the correct smoothness and lightness of texture in the ice cream. When emulsifier concentration is increased there is a greater penetration of fat into the air phase.

The total contribution of emulsifiers is decreased freezing time, improved whipping quality and a production of a dry, fine, stiff texture of ice cream that melts uniformly.

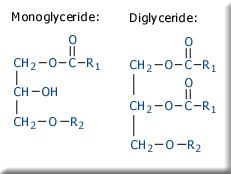

The original ice cream emulsifier was egg yolk but the modern concoction

uses two  basic

materials. These are sorbitan esters such as poly sorbate 80 as well as mono

and di glycerides.

basic

materials. These are sorbitan esters such as poly sorbate 80 as well as mono

and di glycerides.

The main ingredient in egg yolk that was and is still used as an amphiphilic emulsifier is lechthin. Lechthins are a mixture of phospholipids including phosphatidyl choline, phosphatidyl ethanolamines or inositol phosphatides and many others. They are also derived from soybeans and can be chemically modified to provide a wide range of hydrophobic/philic balances for various applications to provide a range of interfacial tensions and effective areas.

Polysorbates

are derived from a sorbitan ester consisting of a glucose alcohol (sorbitol)

molecule bound to a fatty acid, oleic acid, with oxyethylene groups added for

further water solubility. Poly sorbate 80 is small in molecular weight and

produces a low interfacial tension displacing more protein resulting in a very

thin membrane around the fat and a maximum amount of fat destabilization

Polysorbates

are derived from a sorbitan ester consisting of a glucose alcohol (sorbitol)

molecule bound to a fatty acid, oleic acid, with oxyethylene groups added for

further water solubility. Poly sorbate 80 is small in molecular weight and

produces a low interfacial tension displacing more protein resulting in a very

thin membrane around the fat and a maximum amount of fat destabilization

Poly sorbate is also a drying agent that adsorbs water increasing the concentration of sugars and proteins in the serum phase.

Mono and diglycerides are derived from the partial hydrolysis of fats or

oils of animal or vegetable origin. Distilled monoglycerides, especially ones based on fully hydrogenated fats, act

also as starch complexing agents due to their straight carbon chain. This chain

is enveloped by the helical configuration of amylose to form a complex that is

insoluble in water. Altering the chemical properties of other molecules in ice

cream.

Distilled monoglycerides, especially ones based on fully hydrogenated fats, act

also as starch complexing agents due to their straight carbon chain. This chain

is enveloped by the helical configuration of amylose to form a complex that is

insoluble in water. Altering the chemical properties of other molecules in ice

cream.

Stabilizers

The liquid water or serum phase also has structures in it that are affected by colloids and surface phenomena as well as physical nature of diffusion.

One such colloidal attribute is the interaction between the ice crystal/mixture phase. Stabilizing agents affect the balance of molecules between these two phases. The stabilizers are a group of compounds, usually polysaccharides that affect the viscocity of the unfrozen water mixture. They retard or reduce ice crystal growth during storage by reducing the association of the crystals and their diffusion by increasing the viscosity. The slower the rate of migration, the more nucleation is promoted and the greater number of crystals of smaller size that will result. Without the stabilizers, the ice cream would become coarse and icy very quickly due to the migration of this free water and the growth of existing ice crystals.

Stabilizers also firm the ice cream. They aid in suspension of flavoring particles by increasing their solubility in the serum phase. Their thickness stabilizes the foam in the ice cream by this same decrease in diffusional capabilities. During storage, stabilizers play a role in resisting structural changes during “heat shock,” the inevitable temperature cycling during structural changes due to their interaction with diffusional capabilities.

A few such stabilizers

that are used are Carboxymethyl

cellulose (CMC): Locust Bean Gum: Carrageenan: Guar gum and

geltatin. This and many other stabilizers are poly sacharides. This means that

they are polymers of simple sugars that are made of rings and usually are in

the formula C6H12O6. These molecules require

many molecules to solvate them. This hydration is what thickens the serum

phase. They decrease ice crystals and lactose crystals leading to increased

smoothness. Gelatin

and gums are not surface active at the interface. However since the stabilizers attract water molecules

interfacial tension is lowered. Emulsion stability is created due to decreased

availability of water to the interfaces. Increasing the viscosity of the

continuous phase can stabilize an emulsion system. As ice

crystallization begins and water freezes out in its pure form, the

concentration of the remaining solution of sugar is increased due to water

removal. This causes a further lowering of the freezing point. Stabilizers also produce an easy cutoff and

stiffness for packaging and prevent shrinkage in the frozen product while also

slowing down the moisture migration out of the frozen product.

Milk Solids-not-fat

The serum solids or milk solids-not-fat (MSNF) contain the lactose, caseins, whey proteins, minerals, and ash content of the product from which they were derived. They help to give body and chew resistance to the finished product and may be a cheap source of total solids. One draw back includes off flavors. The sources of serum solids for high quality products are sweetened condensed whole or skimmed milk, frozen condensed skimmed milk, buttermilk powder or condensed buttermilk, condensed whole milk, or dried or condensed whey. Each of the components can also be isolated and added separately.

Proteins

Proteins also affect these same basic chemical properties as the stabilizers and emulsifiers including the fat stabilization and the ice/ serum phase. These molecules are larger than the poly sacharides described above and have hydrophobic and hydrophilic parts to them. They tend to unravel at the interfaces between phases associating different pieces of its long chain to different phases. Proteins also have the ability to adsorb water like the poly sachaides and can form their own micelles. The addition of stabilizers and emulsifiers increases the protein concentration in the liquid water or serum phase thickening it more and creating more micelles and increasing the viscosity. Poly sacharides tend to crystallize at this temperature before the proteins. Lactose crystallization can create defects (called tomahawk shape) that cause grainy ice cream, proteins aid in correcting this defect. . It is known from practice that polysorbate 80 can be added subsequent to homogenization, causing proteins to desorb within minutes. It has been reported that the quantity of absorbed material in the absence of an emulsifier is approximately 16% of the total protein in the ice cream mix, and this decreases to <8% in the presence of the polysorbate 80.

Milk protein can be categorized as caseins, whey proteins, and proteins associated with the lipid phase.

Caseins are a family of related phosphoproteins precipitated from raw skim milk at a pH of 4.6 and at a temperature of 20oC as casein micelles with associated calcium. The casein fraction comprises about 80% of the total protein content of milk. A soluble caseinate can be obtained by raising pH to 6.7. Caseins exist in large spherical collodial micelles with calcium phosphate. These micelles comprise 93% (w/w) caseins and range in size from 500 to 3000 A in diameter. The calcium and phosphate play a very important role in maintaining the integrity of the casein micelles, and are commonly referred to as colloid calcium phosphate. Caseins are phosphoproteins

Whey protein is obtained from skim milk after separation of casein in cheese

production. Whey protein is soluble at low pH levels, at which proteins from

other sources coagulate and settle out. Casein is preferentially absorbed over

whey at the interface.

There is a certain level of protein depletion from the fat phase that must be exceeded before partial coalescence occurs. This results in increased hydrophobicity at fat surface, decrease of melting rate, increased shape retention due to fat network and a degree of emulsion destabilization. Proteins also improve the texture of the ice cream

Sweeteners

The consumer usually desires a sweet ice cream. As a result, sweetening agents are added to ice cream mix at a rate of usually 12-16% by weight. Sweeteners improve the texture and palatability of the ice cream, enhance flavors, and are usually the cheapest source of total solids.

In addition, the sugars, including the lactose from the milk components, contribute to a depressed freezing point so that the ice cream has some unfrozen water associated with it at very low temperatures typical of their serving temperatures, -15 to -180 C. Without this unfrozen water, the ice cream would be too hard to scoop. This is a similar action as the stabilizer’ hydration but it is these molecules concentration that directly effects the freezing point. An excess of lactose can lead to the defect of sandiness prevalent when the lactose crystallizes out of solution. Excessive concentrations of lactose in the serum phase may also lower the freezing point of the finished product to an unacceptable level.

![[image]](./g2_doc_files/image010.gif)

This process of freeze concentration continues to very low temperatures. Even at the typical ice cream serving temperature of -16° C, only about 72% of the water is frozen. The rest remains as a very concentrated sugar solution. Thus when temperature is plotted against % water frozen, one gets the phase diagram shown below. This helps to give ice cream its ability to be scooped and chewed at freezer temperatures.

The effect of sweeteners on freezing characteristics of ice cream mixes is demonstrated by the plot on the ice cream freezing curve.

![[image]](./g2_doc_files/image011.gif)

Sucrose is the main sweetener used because it imparts excellent flavor. Sucrose is a disaccharide made up of glucose and fructose. Sucrose is dextrorotatory –meaning it rotates a plane of polarized light to the right, +66.50. With hydrolyzed sucrose the plane of polarization is to the left, “inverted” -200. An acid, plus heat treatment, at concentration above 10%, yields inverted sugar and increases the sweetness.

Other Molecules

Citrate and phosphate ions decrease tendency for fat coalescence (Sodium citrate, Disodium Phosphate) and produce a wetter product. These salts decrease the degree of protein aggregation which effects the amount of protein adhered to the interfaces. Calcium and magnesium ions have the opposite effect, in that they promote partial coalescence. Calcium sulfate, for example, results in a drier ice cream. Calcium and Magnesium increase the degree of protein aggregation. Salts may also influence electrostatic interactions. Fat globules carry a small net negative charge, these ions could increase or decrease that charge as they were attracted to or repelled from surface. Destabilization is also effected by ph, which affects many of the molecules and their ability to be hydrophilic or hydrophobic.

Additives

Fruits, nuts, candy add crystal centers and may enhance lactose crystallization. Nuts pull out moisture from ice cream immediately surrounding the nut thus concentrating the mix.

To maintain the balance between these many different phases is very difficult. Different concentrations of emulsifiers, stabilizers, proteins and fats and the different types of each molecules used effect the properties elicited.

VII.

PROCESSING AND MANUFACTURE

Making ice cream is an art and a science whether in a processing plant or home. In both cases, the ingredients are basic. First, you need cow’s milk and cream. Next come sugar from cane and eggs from chickens. Then, flavoring is added-vanilla, beans, peppermint, or chocolate, for example.

Safety

Concerns

The ice cream you buy at the store or at an ice cream parlor is carefully measured and mixed, and most certainly checked for safety at every step. Scientists make sure of that, safety inspectors make sure that all the mixing, cooling, storage, and packaging protects your health, too. Milk is pasteurized and the eggs are cooked to make sure the final product is not only tasty, not safe.

Basic steps in the manufacturing of ice cream

The basic steps in the manufacturing of ice cream are generally as follows:

-Blend the mix ingredients

-Pasteurize

-Homogenize

-Age the mix

-Flavor

-Freeze

-Package

-Hard Freeze

-Store

Flow diagram for ice cream processing

Blending

First the ingredients are selected based on the desired formulation and the calculation of the recipe from the formulation and the ingredients chosen, then the ingredients are weighed and blended together to produce what is known as the "ice cream mix". Blending requires rapid agitation to incorporate powders, and often high speed blenders are used.

Pasteurization

The mix is then pasteurized. Pasteurization is the biological control point in the system, designed for the destruction of pathogenic bacteria. In addition to this very important function, pasteurization also reduces the number of spoilage organisms such as psychrotrophs, and helps to hydrate some of the components (proteins, stabilizers).

Both batch pasteurizers and continuous (HTST) methods are used.

Batch pasteurizers lead to more whey protein denaturation, which some people feel gives a better body to the ice cream. In a batch pasteurization system, blending of the proper ingredient amounts is done in large jacketed vats equipped with some means of heating, usually steam or hot water. The product is then heated in the vat to at least 69 C (155 F) and held for 30 minutes to satisfy legal requirements for pasteurization, necessary for the destruction of pathogenic bacteria. Various time temperature combinations can be used. The heat treatment must be severe enough to ensure destruction of pathogens and to reduce the bacterial count to a maximum of 100,000 per gram. Following pasteurization, the mix is homogenized by means of high pressures and then is passed across some type of heat exchanger (plate or double or triple tube) for the purpose of cooling the mix to refrigerated temperatures (4 C). Batch tanks are usually operated in tandem so that one is holding while the other is being prepared. Automatic timers and valves ensure the proper holding time has been met.

Continuous pasteurization is usually performed in a high temperature short time (HTST) heat exchanger following blending of ingredients in a large, insulated feed tank. Some preheating, to 30 to 40 C, is necessary for solubilization of the components. The HTST system is equipped with a heating section, a cooling section, and a regeneration section. Cooling sections of ice cream mix HTST presses are usually larger than milk HTST presses. Due to the preheating of the mix, regeneration is lost and mix entering the cooling section is still quite warm.

Homogenization

The mix is also homogenized which forms the fat emulsion by breaking down or reducing the size of the fat globules found in milk or cream to less than 1 µ m. Two- stage homogenization is usually preferred for ice cream mix. Clumping or clustering of the fat is reduced thereby producing a thinner, more rapidly whipped mix. Melt-down is also improved. Homogenization provides the following functions in ice cream manufacture:

- Reduces size of fat globules

- Increases surface area

- Forms membrane

- Makes possible the use of butter, frozen cream, etc.

By helping to form the fat structure, it also has the following indirect effects:

- makes a smoother ice cream

- gives a greater apparent richness and palatability

- better air stability

- increases resistance to melting

Homogenization of the mix should take place at the pasteurizing temperature. The high temperature produces more efficient breaking up of the fat globules at any given pressure and also reduces fat clumping and the tendency to thick, heavy bodied mixes. No one pressure can be recommended that will give satisfactory results under all conditions. The higher the fat and total solids in the mix, the lower the pressure should be. If a two stage homogenizer is used, a pressure of 2000 - 2500 psi on the first stage and 500 - 1000 psi on the second stage should be satisfactory under most conditions. Homogenization begins the process of fat structure formation. After preheating or pasteurization, the mix is at a temperature sufficient to have melted all the fat present, and the fat passes through one or two homogenizing valves, creating globules of 0.5 to 2.0 μm. Immediately following homogenization, the newly formed fat globule is practically devoid of any membranous material due to its tremendous increase in surface area and readily adsorbs amphiphilic molecules from solution. The transit time through a homogenization valve is in the order of 10-5 to 10-6 s. Protein adsorption occurs quickly, but unfolding and rearrangement at the interface may take minutes or even hours to be complete

Aging

The mix is then aged for at least four hours and usually overnight. This allows time for the fat to cool down and crystallize, and for the proteins and polysaccharides to fully hydrate. Aging provides the following functions:

- Improves whipping qualities of mix and body and texture of ice cream

It does so by:

- providing time for fat crystallization, so the fat can partially coalesce;

- allowing time for full protein and stabilizer hydration and a resulting slight viscosity increase;

- allowing time for membrane rearrangement and protein/emulsifier interaction, as emulsifiers displace proteins from the fat globule surface, which allows for a reduction in stabilization of the fat globules and enhanced partial coalescence.

Aging is performed in insulated or refrigerated storage tanks, silos, etc. Mix temperature should be maintained as low as possible without freezing, at or below 5 C. An aging time of overnight is likely to give best results under average plant conditions. A "green" or unaged mix is usually quickly detected at the freezer.

Whipping

The next stage of structure development occurs during the concomitant whipping and freezing step. Air is incorporated either through a lengthy whipping process (batch freezers) or drawn into the mix by vacuum or injected under pressure. Air being incorporated into the mix at this time (especially if pre-whipping devices are being used) is thought to be first surrounded by a proteinaceous membrane. In addition to air incorporation, the whipping process applies a considerable shear stress to the mix, and that shear rate increases as ice crystals form during freezing, likely due to a combination of the addition of particles and to freeze-concentration of the fat and aqueous phase. The continued whipping process and applied shear stress cause the emulsion to undergo partial coalescence or fat destabilization, during which clumps and clusters of the fat globules form and build an internal fat structure or network into the frozen product by entrapping air within the coalesced fat. This coalescing fat interacts with the proteins at the air bubble membrane in a very analogous manner to the whipping of heavy cream. Partial coalescence occurs in the absence of air, but the presence of air during shear stress will increase partial coalescence considerably. Likewise, the applied shear stress also increases partial coalescence considerably compared to the sparging of air.

Freezing and Hardening

Following mix processing, the mix is drawn into a flavor tank where any liquid flavors, fruit purees, or colors are added. The mix then enters the dynamic freezing process that both freezes a portion of the water and whips air into the frozen mix. The "barrel" freezer is a scraped-surface, tubular heat exchanger, which is jacketed with a boiling refrigerant such as ammonia or freon. Mix is pumped through this freezer and is drawn off the other end in a matter of 30 seconds, (or 10 to 15 minutes in the case of batch freezers) with about 50% of its water frozen. There are rotating blades inside the barrel that keep the ice scraped off the surface of the freezer and also dashers inside the machine which help to whip the mix and incorporate air.

VII.

Marketing Considerations

Demand

According to a Nielsen survey of supermarket sales, ice cream is America’s favorite dessert. The demand for ice cream always exists, and it tends to grow, not to decrease. And many producers of ice cream are right when say that this business is paying, because each American consumes a yearly average of 23.75 quarts of ice cream, ice milk, sherbet, ice and other commercially produced frozen dairy products, which translates to 1.6 billions gallons.

However the Northern Central states have the highest per capita consumption of ice cream at 41.7 quarts. The top three cities in America that purchase the most ice cream on a per capita basis are: Portland, Oregon; St Louis, Missouri; and Seattle, Washington.

Flavors

The equipment is intended for making the ice cream based on natural ingredients: milk, cream, water, butter, sugar, condensed milk and naturals thickening agents. The lines may be used to produce many varieties of the ice cream: ‘plombir’, creamy, dairy, chocolate and flavored ice creams. Therefore, the Supermarket Sales is divided by Flavor Category.

1. Vanilla - 28 percent

2. Fruit flavors - 15 percent

3. Nut flavors - 13.5 percent

4. Candy mix-in flavors - 12.5

percent

5. Chocolate - 8 percent

6. Cake and cookie flavors - 7.5

percent

7. Neapolitan - 7 percent

8. Other - 5.5 percent

9. Coffee/mocha - 3 percent

Demand for

“natural” ice cream

Based on natural hydrocolloids, the product portfolio of FMC Biopolymer is well adapted to the companies’ customers and the consumer focus on products that are natural, biodegradable, and sourced from vegetable origins.

The driving forces behind this continuous trend are the general improvement in consumers’ health awareness and new technology. Recently, this trend has been fueled by more stringent food and safety regulations being enacted in many countries. The trend is a global phenomenon, but these forces have traditionally been most pronounced in Northern Europe and North America, where consumers have been concerned about replacing so-called “unhealthy” ingredients with “healthy” ones for quite some time.

Alginate has earned a reputation as a “healthy” ingredient. Alginate and carrageenan are completely natural, renewable and biodegradable. When used in foods or pharmaceutical products, alginate and carrageenan are either metabolized or absorded in the course of the biological cycle. In line with the opinions of western researchers and weight reduction experts who recommend cutting down on dietary fats and sugar, in recent years there has been explosive growth in low-calorie and low-fat products.

In other words, there is growing demand for products containing low levels of fat or fat substitutes or no fat at all. Yet it is not easy to replace fat. Its appearance, texture and taste govern our perception of the food we eat, and fat often plays an important role in these factors. In fatty, water products, it is essential that the texture remains stable and leaves a good ‘feeling’ in the mouth.

On the other hand, it is possible to reduce fats during the production of goods such as margarine, mayonnaise, dressing, sauces, creams, yogurts and ice cream, by replacing it with water. However, such substitution will have an effect on the products’ texture, which must then be reconstructed using texturing agents such as gelatin, alginate, carrageenan and microcrystalline cellulose.

In addition to its stabilizing properties, there are other reasons that hydrocolloids like carrageenan and alginate offer considerable advantages, thanks to their vegetagle origins, as opposed to gelatin, which is made from slaughterhouse offal

Kosher (no

milk with animal proteins)

At its most basic level ice cream is a combination of cream, milk, sugar, and basic flavoring. For manufacturers, the ideal ice cream has a smooth texture, full flavor, slow-melt qualities, and long freezer life. Due to all the additives, ice cream needs supervision. Franchised retail outlets that make the products in the store rely on ice cream mixes as the base for their ice cream and , therefore, each of them requires supervision.

Today, perhaps the primary problem for koshers observers is additions to ice cream, most notably marshmallows, candies, and baked goods, all of which independently require kosher supervision. There are currently more than a thousand flavors of ice cream in the United Sates. Today almost every national brand is under kosher supervision including Haagen-Dazs, Ben & Jerry’s, Godiva, Starbucks and Edy’s Dreamery.

Cost for

production & purchase

Like all food products, a premise is required that conforms to the hygiene legislation in the EU Directive 92/46/EEC.

For ice cream production, one needs a processing area, a cold room and a freezer room, an area to store dry ingredients and an area to store packaging. Equipment for processing is very specific and quite expensive. A mixing vat, homogenizer, freezer, and fruit blender would cost approximately $50,000. This would have a production capacity of 80-100 liters of ice cream per hour.

Cost of 1 liter of dairy ice cream mix (38% T.S. & 12% Fat) = $1.10

Overrun 100%

Cost of 1 liter of dairy ice cream $0.55

Cost of packaging $0.15

Distribution & retail margin $1.00

Total Retail $3.45

Product Margin $1.75

Cost of Purchase

Examples of ice cream Prices

Haagen-Dazs $7.18/L

Ben & Jerry’s $7.50/L

Carte D’Or $2.99/L

Darina Allen $3.50/L

Paganni $2.59/L

Sales

According to a recent study conducted by “ The U. S. Market For Ice Cream And Other Frozen Desserts “, ice cream and other frozen dessert sales totaled $11.5 billion in 1999, up 2.9% from 1998. The biggest seller in the frozen dessert category is packaged ice cream with captured more than 52% of the market share in 1999 with sales totaling $6 billion. Frozen novelties are second in sales with a 35% market share equaling 4.25 billion in 1999. Sales of frozen novelties increased more than 20% between 1994 and 1999. Overall sales projections for ice cream and frozen novelties will grow almost 8% between 1999 and 2004.

Certain positive and negative factors are affecting market growth including the rising cost of milk fat, cooler weather patterns, health conscious consumers, the baby boom echo, the U. S. economic boom and globalization of economy and culture. The latter, is evidenced by the introduction of products from Asia, Latin America and Eastern Europe.

IX.

Suppliers

-Ben and Jerry’s

-Perry’s Ice Cream

-Breyer’s

-Eddy’s

- Haagen-Dazs

X. Conclusion

Something seeming so simple and yet still so complex can still be enjoyed as it has been for centuries in pure sweet bliss but the enjoyment only grows when one can understand the physical principals behind ice cream.

XI. References

Books

Dickinson, E., and Walstra, P. Food colloids and polymers: stability and mechanical properties New York, Springer Verlag, 1993

Dickinson, E., Lorient D. Food macromolecules and colloids New York, Springer Verlag, 1995

Fennema, Owen R. Food Chemistry. New York, Marcel Dekker, 1996

Papers

Bolliger, S., H. Wildmoser, H. D. Goff, and B. W. Tharp. 2000. Relationships between ice cream mix visco-elasticity and ice crystal growth in ice cream. Internat. Dairy J. 10: 791-797.

Goff, H. D and P. Spagnuolo. 2001. Effect of stabilizers on fat destabilization measurements in ice cream. Milchwissenschaft. 56: 450-453.

Goff, H.D. 2000. Controlling ice cream structure by examining fat protein interactions. Australian J. Dairy Technol. 55: 78-81.

Goff, H. D. 1997. Colloidal aspects of ice cream - a review. Int. Dairy J. 7: 363-373.

Goff, H. D. 1997. Instability and partial coalescence in dairy emulsions. J. Dairy Sci. 80: 2620-2630.

Goff, H. D., K. B. Caldwell, D. W. Stanley and T. J. Maurice. 1993. The influence of polysaccharides on the glass transition in frozen sucrose solutions and ice cream. J. Dairy Sci. 76: 1268-1277.

Websites

http://www.foodsci.uoguelph.ca/dairyedu/icecream.html

http://www.polsci.wvu.edu/Henry/Icecream/Icecream.html

http://www.elsevier.com/locate/idairyj

http://www.foodproductdesign.com/archive/1997/0897AP.html