![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Package Pusher

6 bar Mechanism

Introduction

This tutorial uses a package pusher as an example to teach the kinematic and dynamic analysis using Solid Edge and Dynamic Designer.

|

|

|

|

Package Pusher |

6 bar Mechanism |

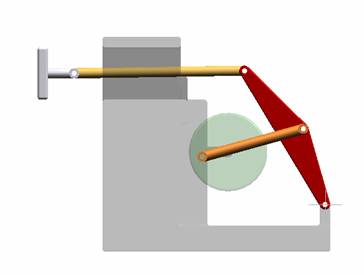

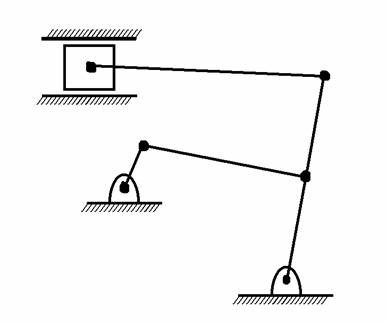

The mechanism used in this example is simple 6 bar Mechanism. A 6 bar Mechanism consists of six links with one being designated as frame (or ground). It is connected by five pin joints one slider and one crank.

As designated in the figure, there are six links. Link 1 is the slider. Link 2, link 3 and link 5 are connecting links. Link 4 is the crank. Link 6 is ground.

The following table summarizes the joints.

|

Joint Number |

Formed between links |

Joint type |

|

1 |

Link 1 and Link 2 |

Revolute (or Pin) |

|

2 |

Link 2 and Link 3 |

Revolute (or Pin) |

|

3 |

Link 3 and Link 5 |

Revolute (or Pin) |

|

4 |

Link 3 and Link 6 |

Revolute (or Pin) |

|

5 |

Link 1 and Link 6 |

Translational (or Slider) |

|

6 |

Link 4 and Link 5 |

Revolute (or Pin) |

|

7 |

Link 4 and Link 6 |

Revolute (or Pin) |

Degrees of Freedom: According to Gruebler’s equation,

![]()

where F = Degrees of Freedom (DOF)

n = total number of links in a mechanism

![]() = total number of primary joints (pins or sliders)

= total number of primary joints (pins or sliders)

![]() = total number of higher-order joints(cams or gears)

= total number of higher-order joints(cams or gears)

we have,

F = 3(6-1) – 2(6+1) – 0

= 15 – 14 - 0

= 1.

Hence, 6 bar mechanism has 1 DOF. In other words, 6 bar mechanisms are constrained or fully operated with one driver.

Click here to get the compressed (Solid Edge) part files.